In luxury watch box production, a flawless lacquer finish isn’t just for looks—it’s a signal of craftsmanship, quality, and longevity. The number of lacquer layers directly affects both the gloss and durability of the surface.

So how many layers are truly necessary, and what’s the risk of going too far—or not far enough?

After years of hands-on work with piano lacquer finishes, I’ll break down how the layering process works, and why getting it right is critical for premium wooden watch boxes.

Each layer of lacquer plays a specific role: sealing the surface, building depth, protecting the wood, and amplifying the gloss. A well-layered finish isn’t just cosmetic—it’s functional.

For luxury watch boxes, the lacquer layering1 process determines the box’s resistance to wear, scratches, and environmental changes.

The Function of Each Lacquer Layer

- Base Layers (1–2 coats): Penetrate wood pores and seal the surface.

- Build-Up Layers (3–7 coats): Add volume, protect against impact and moisture, and create body for polishing.

- Top Layers (8–12+ coats): Refine smoothness, clarity, and final mirror-like gloss.

In high-end production, I never use fewer than 8 layers. The final look—and feel—depends on this foundation.

How many layers are typically needed for optimal durability and shine?

For luxury wooden watch boxes, 8 to 12 layers of lacquer2 are typically needed to achieve both durability and high-gloss elegance3.

The exact number depends on the wood type, desired finish depth, and application method.

Typical Lacquer Layer Breakdown

| Layer Stage | Purpose | Grit Between Coats |

|---|---|---|

| Sealer (1–2) | Surface sealing, grain lock | 400–600 |

| Build-Up (3–7) | Surface leveling, gloss foundation | 800–1000 |

| Topcoat (8–12+) | Depth, reflectivity, protection | 1200–2000 |

✔ 8 layers = standard for semi-gloss luxury finish4

✔ 10–12 layers = high-gloss, piano-style mirror finish

I’ve found 10 layers with intermediate sanding offers the best trade-off between gloss depth and production time, especially for watch boxes with clear lacquer over dark wood like walnut or ebony.

What happens if too few or too many lacquer layers are applied?

Applying too few lacquer layers can leave the surface vulnerable to damage. Too many, and you risk poor curing5, cracking, or a cloudy, overly plastic look.

Risks of Too Few Layers

- Thin Surface Film: Less protection from scratches or environmental exposure.

- Uneven Sheen: Inconsistent gloss levels, especially over open-grain woods.

- Poor Depth: The finish lacks that luxurious, mirror-like visual depth.

Risks of Too Many Layers

- Solvent Lock-In: Inner coats may not fully cure, leading to microcracks later.

- Brittleness: Excess lacquer thickness can flake or crack with temperature changes.

- Cloudiness: Over-layering can obscure the natural wood grain beneath.

One of my earlier mistakes was layering too quickly without allowing proper curing. A month later, hairline cracks appeared in the corners—teaching me that more is not always better.

How does each additional layer impact the surface smoothness6 and depth of gloss7?

Every additional lacquer layer contributes to greater smoothness, enhanced reflectivity, and visual depth. But only if it’s properly applied and sanded.

The Role of Each Layer in Gloss Development

✔ Layer 1–2: Flattens wood grain and seals it.

✔ Layer 3–5: Builds surface body and starts creating reflectivity.

✔ Layer 6–8: Eliminates micro-defects and adds visual depth.

✔ Layer 9–12: Delivers that unmistakable mirror gloss8 you see on grand pianos.

The key is consistency. Each layer must be uniform, fully dry, and perfectly sanded. That’s how we achieve the signature “wet” look clients expect.

What techniques are used between layers to enhance adhesion and prevent cracking?

The secret to a strong, crack-free lacquer finish isn’t just the lacquer itself—it’s how you treat the layers in between.

Sanding and surface preparation between each coat ensures adhesion and prevents tension buildup that leads to cracking.

Inter-Layer Techniques

- Sanding Between Layers9: Light sanding with 800–1500 grit removes surface defects and roughness.

- Cleaning Residue10: Each layer is wiped with alcohol or tack cloth to remove dust and oils.

- Flash-Off Periods11: Allowing solvents to evaporate before curing prevents trapped moisture or gases.

Pro Tips

- Always sand wet or use dust-free abrasives to avoid micro-scratches.

- Use crosshatch sanding patterns to avoid swirl marks.

- Never rush re-coating—solvent release time is critical.

In my workshop, we’ve standardized a 3-hour rest between mid-layers and a 12-hour final cure before polishing. It adds a day to the lead time but removes 90% of lacquer-related defects.

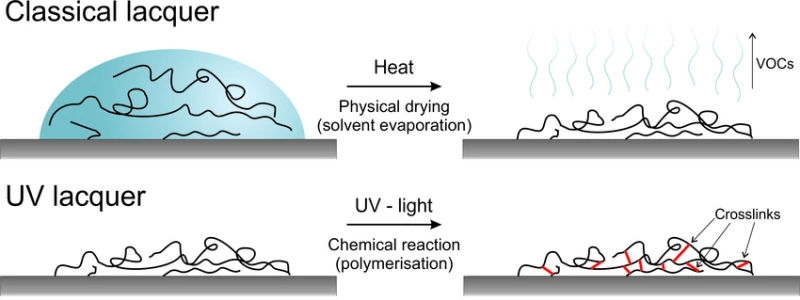

How does proper curing time between layers influence the final result?

Curing time between lacquer layers is what allows the finish to “settle” and harden. Without it, the surface can crack, blush, or dull over time.

A rushed lacquer job may look fine on day one, but within weeks, flaws appear.

Why Curing Time Matters

- Solvent Evaporation: Prevents bubble formation and soft spots.

- Surface Shrinkage Management: Allows layers to stabilize, avoiding surface warping.

- Hardness Development: Full polymerization creates a durable, long-lasting topcoat.

Recommended Curing Schedule

| Stage | Minimum Cure Time |

|---|---|

| Base Coats | 2–4 hours |

| Mid Coats | 4–6 hours |

| Final Topcoats | 12–24 hours |

✔ Use forced-air drying or low-temperature baking to accelerate without compromising quality.

I’ve seen finishes that looked flawless initially start to bubble after a few weeks in a warm climate—all because one of the mid-coats wasn’t fully cured before re-coating.

Conclusion

The number of lacquer layers—and how they’re applied—defines both the look and longevity of a luxury watch box.

With too few coats, the box lacks gloss and protection. With too many, it risks cracking and clouding. When done right—with proper sanding, curing, and layering—each coat builds toward a flawless, mirror-smooth finish that reflects not just light, but the brand’s commitment to quality.

Brand Name: WoodoBox

Slogan: Custom Wooden Boxes, Crafted to Perfection

Website: www.woodobox.com

-

Understanding lacquer layering is crucial for appreciating its role in enhancing the durability and aesthetics of luxury watch boxes. ↩

-

Discover expert insights on achieving the perfect lacquer finish for luxury wooden items, ensuring both durability and elegance. ↩

-

Learn techniques and tips for achieving a stunning high-gloss finish on wood, perfect for luxury items. ↩

-

Explore the characteristics and application methods of semi-gloss finishes to enhance your woodworking projects. ↩

-

Learn about the factors that lead to poor curing in lacquer finishes to avoid common pitfalls and ensure a flawless application. ↩

-

Understanding surface smoothness is crucial for achieving high-quality lacquer finishes. Explore this link to enhance your knowledge. ↩

-

The depth of gloss significantly impacts the aesthetic appeal of finishes. Discover more about this essential aspect. ↩

-

Achieving a mirror gloss is a hallmark of quality in finishes. Learn the techniques that can help you master this look. ↩

-

Understanding the significance of sanding can greatly improve your finishing technique and reduce defects in your projects. ↩

-

Exploring the impact of cleaning residue can enhance your knowledge of surface preparation for better adhesion. ↩

-

Learning about flash-off periods can help you prevent issues like trapped moisture, ensuring a flawless finish. ↩