Piano lacquer offers a stunning mirror-like finish, but it’s also sensitive—especially to temperature changes. One of the biggest challenges I’ve seen in large-scale production is keeping that perfect finish intact when a wine box travels across different climates.

So how do we prevent micro-cracking and ensure long-lasting lacquer performance?

Based on years of experience finishing high-gloss wooden wine boxes1, I’ll walk you through how we manage this issue, from materials to environment.

Why does piano lacquer become vulnerable to cracking with temperature fluctuations?

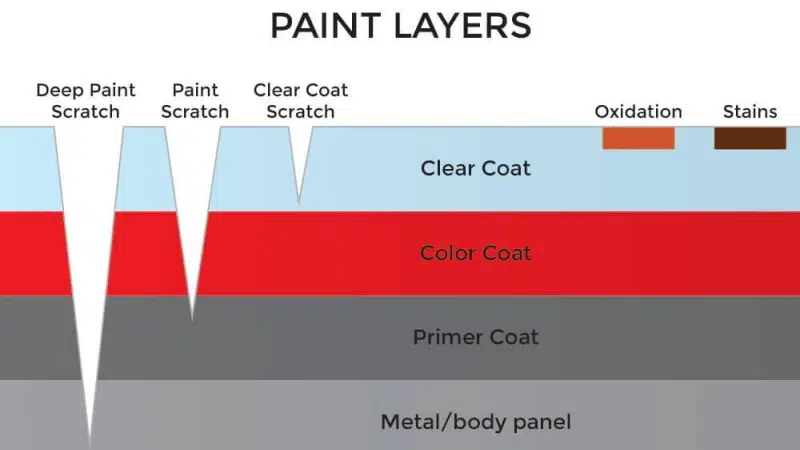

Piano lacquer (usually nitrocellulose or polyester-based) is hard, but not highly flexible. When temperatures change quickly, the wooden substrate expands or contracts faster than the lacquer can handle—causing micro-cracks2.

These cracks often appear as faint spider lines or hairline fractures under the gloss layer. They’re usually invisible at first, but they expand over time—especially in drier or colder climates.

Key Causes of Micro-Cracking

- Rapid cooling or heating during shipping

- High humidity followed by dry storage

- Poor bonding between layers or improper curing

- Rigid lacquer with low elasticity

I’ve seen entire batches of wine boxes returned due to invisible cracks that only showed up after exposure to winter shipping routes. It’s a costly mistake we now work hard to avoid.

What materials and base coatings help absorb thermal expansion effectively?

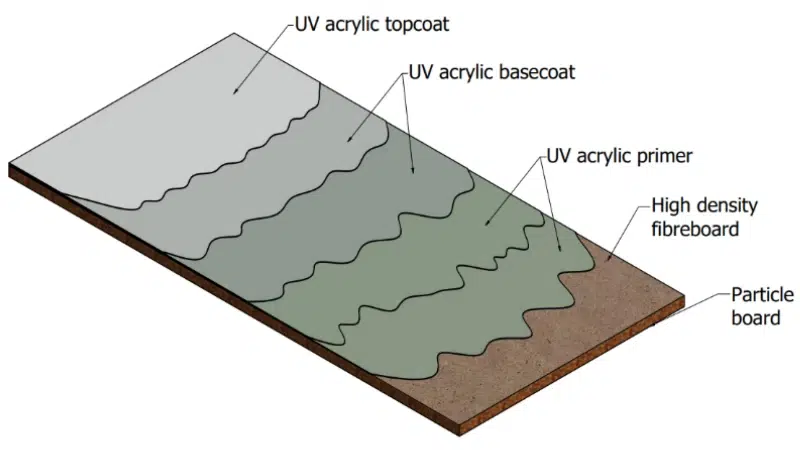

The best way to reduce lacquer stress is by starting with a stable base2. Wood selection, grain sealing, and flexible primer systems3 all contribute to how well the surface absorbs movement.

Recommended Materials and Preparations

- Use stable, kiln-dried hardwoods like mahogany, walnut, or engineered cores with low moisture variability.

- Bewerbung elastic sanding sealers4 or primers that flex slightly under stress (e.g., polyurethane-based primers).

- Fill the grain completely—especially on open-grain woods—to reduce uneven shrinkage.

Surface Preparation Steps

- Moisture content: 8–10% before finishing

- 2–3 coats of flexible sealer before any color or lacquer

- Sand flat with 400-grit before layering clear coats

On export orders, we avoid using solid pine unless laminated—it’s too soft and moves too much across seasons, putting stress on the finish.

How does proper curing time and method strengthen lacquer stability?

Most cracking problems start with poor curing. Even if the lacquer feels dry to the touch, internal solvents5 may still be evaporating. If the box is packed or exposed to temperature swings6 too early, the finish won’t survive.

Ideal Curing Conditions

| Schritt | Details |

|---|---|

| Flash-off Time | 10–20 minutes between light coats |

| Intercoat Cure | 12–24 hours minimum between full coats |

| Final Cure | 5–7 days in 20–25°C, 50–60% RH |

| Optional Baking | 40–45°C for 2–3 hours (for PU/polyester) |

✔ Avoid stacking boxes during cure period

✔ Keep air moving, but not dusty or too dry

✔ Avoid curing under direct sun or draft zones

We’ve made it standard to allow 7 full days of climate-controlled curing before polishing. It slows down production, but eliminates cracking and shrinkage complaints.

What role does lacquer composition play in resisting environmental stress?

Not all lacquers behave the same under heat or cold. Nitrocellulose, acrylic, polyurethane, and polyester each have different hardness, flexibility, and solvent content.

Lacquer Comparison Chart

| Type | Flexibility | Dauerhaftigkeit | Crack Resistance | Finish Quality |

|---|---|---|---|---|

| Nitrocellulose | Niedrig | Mäßig | Messe | Warm, rich tone |

| Acrylic | Mäßig | Gut | Gut | Soft, plastic feel |

| PU (Polyurethane) | Hoch | Sehr hoch | Very Good | Clear, tough |

| Polyester | Niedrig | Ausgezeichnet | Schlecht | Glass-like, brittle |

✔ For large wine boxes, we recommend polyurethane-based systems7

✔ For dark colors with heavy gloss, polyester is viable—but needs better base prep and storage control

We learned early on that mixing lacquer brands8 or hardeners—even slightly—leads to unpredictable shrinkage. Stick with one system from sealer to topcoat.

How can packaging and storage methods reduce exposure to extreme conditions?

Even a perfectly cured finish can crack if the box is exposed to sudden cold or heat during transport. Packaging and warehousing play a huge role in protecting the surface.

Best Practices for Shipping and Storage

- Use foam or bubble-wrap sleeves to cushion temperature swings9

- Double-box with insulation if shipping to cold climates

- Avoid shrink-wrapping until the box is fully acclimated

- Keep finished stock in 18–25°C storage until shipment

- Allow 24–48 hours of acclimation at destination10 before unboxing

✔ Mark boxes with “Protect from Extreme Cold/Heat”

✔ Add silica gel packs to avoid condensation

We once shipped a full container to Northern Europe during winter. The only boxes that cracked were those closest to the container walls—now we always load high-gloss units in the center, surrounded by buffer cartons.

What quality control steps can detect early signs of micro-cracking before shipping?

Many micro-cracks are invisible in flat lighting. You need targeted inspection methods to catch them before they reach customers.

QC Techniques for Lacquer Inspection

- Verwenden Sie high-angle raking light11 (4000K LED strips at 30° angle)

- Inspect from multiple directions—never just overhead

- Use cotton gloves to feel for cracks—your fingertips catch what your eyes may miss

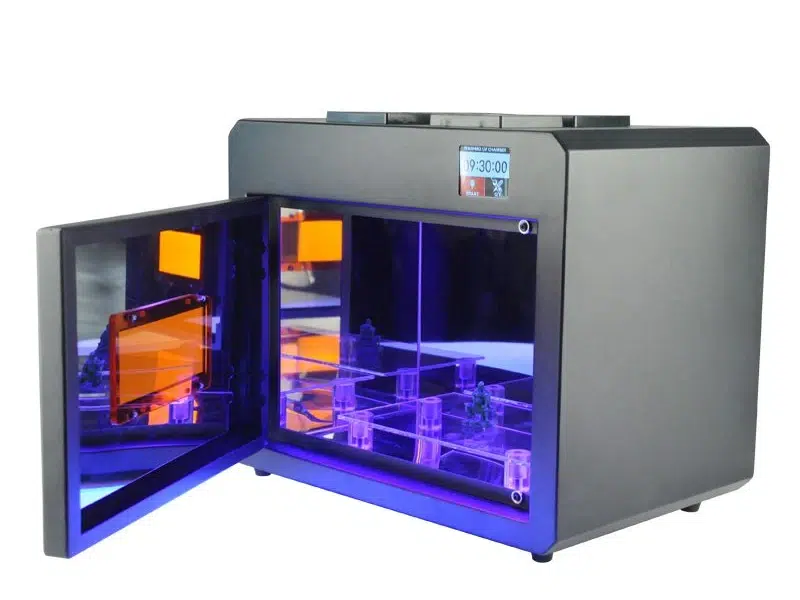

- Perform climate chamber testing12 on sample units if shipping overseas

- Track batch curing dates to ensure minimum rest time is met

✔ Reject any unit with gloss distortion, halo lines, or “stretch marks” in the surface

✔ Include photo documentation13 with each batch

We keep a light tunnel in our inspection room—no box leaves without a full rotation under white and yellow light. That 2-minute step has saved us from costly returns more than once.

Schlussfolgerung

Preventing piano lacquer cracks in high-gloss wine boxes is all about control—of materials, curing, climate, and even packaging.

To reduce risk:

- Use stable substrates and flexible base coats

- Cure slowly and thoroughly in controlled conditions

- Choose lacquers suited for temperature resilience

- Package and store boxes to reduce environmental shock

- Inspect each box under proper lighting before shipment

When every step is intentional, your finish stays flawless—no matter how far it travels.

Markenname: WoodoBox

Slogan: Maßgefertigte Holzkisten, handwerklich perfekt gefertigt

Website: www.woodobox.com

-

Discover best practices for finishing high-gloss wooden wine boxes to maintain their beauty and integrity over time. ↩

-

Understanding the concept of a stable base is crucial for effective woodworking and reducing finish stress. Explore this link for in-depth insights. ↩ ↩

-

Flexible primer systems are essential for accommodating wood movement. Discover their benefits and applications in woodworking by exploring this resource. ↩

-

Elastic sanding sealers play a vital role in protecting wood finishes. Learn more about their properties and advantages in this informative link. ↩

-

Learn how internal solvents impact the curing process and the overall durability of lacquer finishes. ↩

-

Explore the effects of temperature fluctuations on lacquer stability to ensure a flawless finish. ↩

-

Polyurethane-based systems offer superior durability and flexibility, making them ideal for large wine boxes. Discover more about their benefits here. ↩

-

Mixing lacquer brands can lead to unpredictable results. Learn why consistency is key for achieving the best finish. ↩

-

Understanding the impact of temperature swings can help you implement better shipping practices to protect your products. ↩

-

Discover the significance of acclimation in ensuring product quality and preventing damage during transport. ↩

-

Understanding the role of high-angle raking light can enhance your inspection techniques, ensuring better detection of micro-cracks. ↩

-

Exploring climate chamber testing can provide insights into how environmental factors affect product integrity, crucial for quality control. ↩

-

Learning about photo documentation can improve your QC processes by ensuring accountability and traceability in inspections. ↩