In luxury perfume packaging, visual harmony matters. When your product relies on high-gloss lacquer finishes, even the slightest color shift between batches can compromise the overall brand image.

So how do manufacturers ensure that every box—whether produced today or six months from now—matches perfectly in color and sheen?

In this article, I’ll share the techniques and tools we use in the industry to keep high-gloss perfume boxes consistent in tone, depth, and surface uniformity.

Why is color consistency1 so important in luxury perfume packaging?

Luxury brands depend on visual precision to convey quality and sophistication. A mismatch in lacquer color can break that consistency, weaken brand perception, and affect customer trust.

When a customer places two boxes side by side, they expect identical color, gloss, and clarity—even if produced in separate batches.

Why Color Uniformity Matters

- Brand Identity: Color is a visual signature. Inconsistency weakens recognition.

- Customer Experience: Mismatched packaging sends the wrong message about quality control.

- Retail Display Impact: Discrepancies are especially noticeable under retail lighting.

I once had a client reject 300 units because the red lacquer turned slightly pink under warm store lights. That incident led us to overhaul our entire color-matching protocol.

What factors can cause color shifts during the lacquer mixing and application process?

Color shifts can happen at multiple stages—from the lacquer mixing table to the spray booth. Environmental factors, operator technique, and even pigment age can alter final results.

Key Causes of Color Variation

✔ Inconsistent Pigment Mixing2

Manual measurements or uneven stirring result in shade fluctuations.

✔ Lacquer Thickness

More layers can deepen or darken colors; fewer coats appear lighter.

✔ Spray Gun Settings3

Nozzle size, air pressure, and distance from the surface impact how light or dark the color appears.

✔ Drying & Curing Conditions4

Temperature and humidity affect lacquer flow and pigment distribution.

✔ Batch-to-Batch Resin Differences

Even slight changes in resin base or gloss additive can shift perceived color under light.

The human eye may not catch a 3% difference—but side-by-side under showroom LEDs, it becomes obvious. That’s why we rely on calibrated tools, not guesswork.

How do manufacturers standardize color formulas across different production batches?

The secret to color consistency is a documented, reproducible formula—and the discipline to follow it precisely.

At our workshop, every lacquer color is tied to a master formulation5, which includes not only the pigment ratios, but spray parameters, curing time, and environmental conditions.

Techniques for Formula Standardization

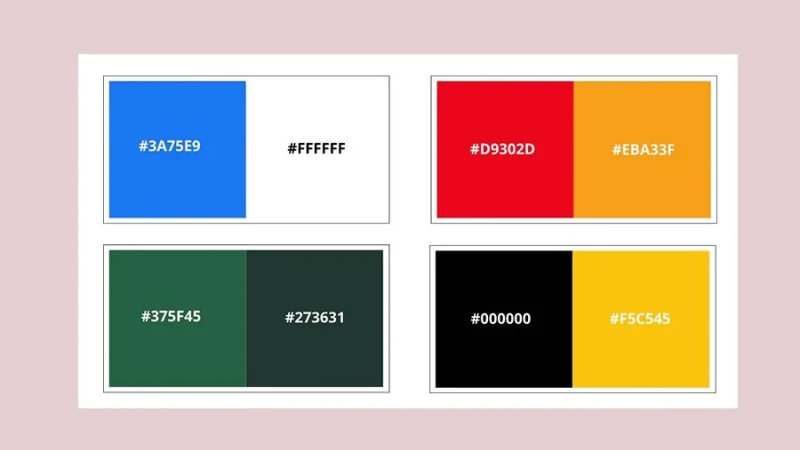

✔ Color Matching by Weight, Not Volume6

Pigments and additives are weighed to 0.01g accuracy for each mix.

✔ Batch Coding

Every mix is labeled and recorded, including lot numbers for pigments and solvents.

✔ Small-Batch Testing Before Full Run

Each production run starts with a control sample tested against a color standard.

✔ Use of Base Color Concentrates

These are pre-mixed master tints stored in sealed containers, reducing variation.

✔ Lacquer Viscosity Control7

Thinner-to-solids ratio is maintained using viscosity cups and timers.

Our lacquer lab has a “master board” with original sprayed samples. Every new batch must match visually and digitally before approval.

What tools and technologies are used to measure and match color accurately?

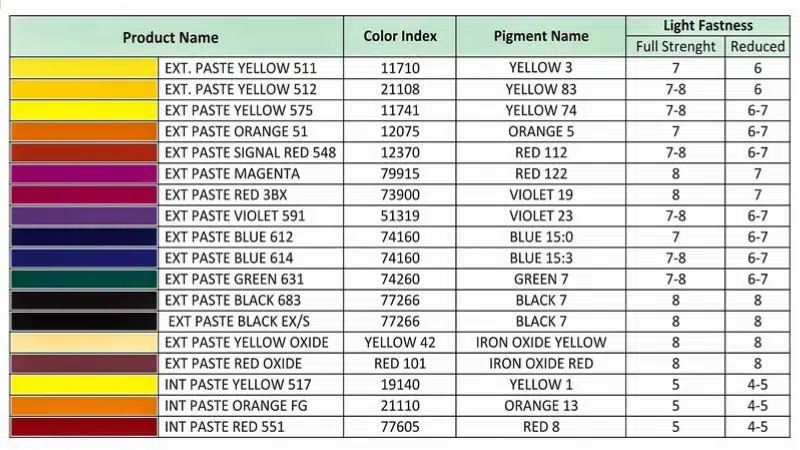

Human eyes are not reliable enough when it comes to high-gloss color matching. We use color measurement tools to quantify shade, tone, and reflectivity with precision.

Key Instruments for Color Matching

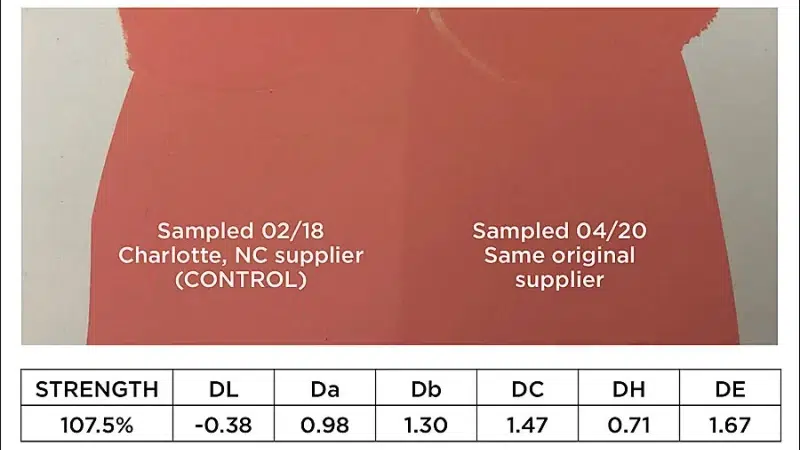

✔ Spectrophotometer8

Measures reflected light across the visible spectrum, producing a unique “color fingerprint” (Lab* values).

✔ Gloss Meter9

Measures surface reflectivity in Gloss Units (GU) to match sheen levels.

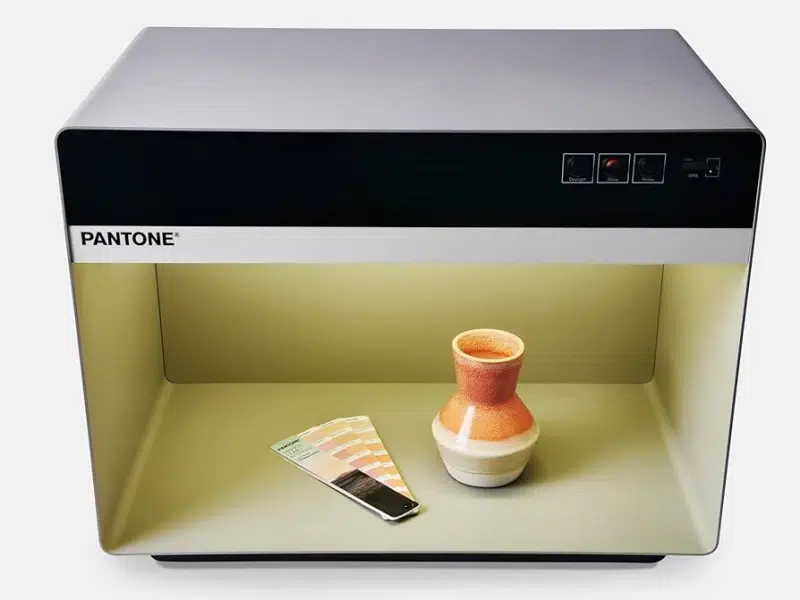

✔ Light Booths10

Simulates multiple lighting conditions (D65 daylight, warm white, cool white) for accurate visual inspection.

✔ Color Standard Chips

Physically stored color swatches sprayed from the master formula for side-by-side comparison.

| Tool | Function | Accuracy |

|---|---|---|

| Spectrophotometer | Measures exact color (Lab*) | ±1 ΔE |

| Gloss Meter | Measures reflectivity at 60° angle | ±2 GU |

| Light Booth | Ensures match under different lights | Visual |

We once spotted a barely visible mismatch on a navy blue box using a spectrophotometer—without it, we’d have missed the deviation completely.

How does lighting in the workshop affect color perception during quality checks?

Lighting can dramatically change how lacquer color appears, especially with reflective high-gloss finishes. That’s why controlled lighting11 is essential during inspection.

How Lighting Impacts Color Perception

- Natural vs. Artificial Light: Colors look different under daylight, halogen, and LED.

- Light Temperature (Kelvin): Warm lights (2700K) add yellow tones; cool lights (6500K) add blue.

- Gloss Level Interaction: Higher gloss reflects surroundings, distorting color perception.

Best Practices for Lighting Control

✔ Use D65 Standard Daylight Bulbs12

Industry standard for accurate color inspection.

✔ Install Viewing Booths with Multiple Light Modes

Check the product under at least three lighting conditions before approval.

✔ Avoid Fluorescent Tubes

These create uneven lighting and distort hue.

✔ Calibrate Booth Lighting Annually

Bulb degradation affects consistency over time.

Our QC area has a fixed booth with D65, TL84, and incandescent modes. It’s standard practice to approve all gloss-finished boxes under every setting.

What are the best practices for storing lacquer materials to avoid pigment separation or degradation?

Proper storage of lacquer materials13 prevents changes in color formulation caused by pigment settling, oxidation, or contamination.

Storage isn’t just about putting things on a shelf—it’s about maintaining chemical integrity batch after batch.

Best Practices for Lacquer Material Storage

✔ Store in Sealed, Opaque Containers

Prevents exposure to UV light, which degrades pigments and solvents.

✔ Keep in Temperature-Controlled Rooms14 (18–25°C)

Extreme heat causes pigment breakdown and solvent evaporation.

✔ Regular Agitation of Stored Pigments15

Even when not in use, shake or stir every few weeks to avoid settling.

✔ Label Everything with Dates and Batch Numbers

Ensures rotation of stock and traceability of issues.

✔ Avoid Mixing Brands or Batches Mid-Run

Different pigment suppliers may vary slightly in concentration or tone.

I once had a burgundy pigment stored too close to a heater. It oxidized just enough to shift color subtly—only noticeable when paired with the original batch under display lights.

Conclusion

Color consistency is non-negotiable in luxury high-gloss perfume boxes. From precise formulation and controlled environments to advanced tools and post-finish checks, every detail matters.

To achieve perfect consistency across batches:

- Start with standardized formulas and precision weighing.

- Use colorimetric tools, not just the human eye.

- Control the spray environment and lighting conditions.

- Store your materials correctly to avoid future surprises.

Consistency equals trust—every time a customer opens your box, the color should reflect the same luxury they’ve come to expect.

Brand Name: WoodoBox

Slogan: Custom Wooden Boxes, Crafted to Perfection

Website: www.woodobox.com

-

Understanding color consistency can enhance your brand's visual identity and customer trust, crucial for luxury markets. ↩

-

Understanding the impact of pigment mixing can help ensure color consistency in your projects, leading to better results. ↩

-

Exploring spray gun settings can enhance your application technique, ensuring optimal color results and reducing waste. ↩

-

Learning about drying and curing conditions can help you control the final appearance of your lacquer finishes, ensuring quality. ↩

-

Understanding master formulations can enhance your knowledge of color consistency in manufacturing processes. ↩

-

Exploring the significance of weight-based color matching can improve your production accuracy and quality control. ↩

-

Learning about viscosity control methods can help you achieve better results in your lacquer applications. ↩

-

Explore this link to understand the technology behind spectrophotometers and their role in precise color measurement. ↩

-

Learn about gloss meters and their importance in achieving the perfect sheen in color matching. ↩

-

Discover how light booths simulate different lighting conditions for accurate color assessment. ↩

-

Understanding controlled lighting can enhance your quality checks and ensure accurate color perception in your products. ↩

-

D65 bulbs are crucial for accurate color representation; exploring this can improve your inspection processes. ↩

-

Understanding proper storage techniques is crucial for maintaining the quality and longevity of lacquer materials. Explore this resource for expert insights. ↩

-

Temperature control is vital for preserving the integrity of lacquer materials. This link will provide detailed information on the impact of temperature on storage. ↩

-

Regular agitation can significantly enhance the quality of stored pigments. Discover more about this practice and its benefits through this resource. ↩