Uma caixa de perfume de luxo deve ter um aspeto e um toque impecáveis - até ao mais pequeno recorte.

Envolver de forma limpa formas interiores complexas com couro PU requer precisão, paciência e os materiais certos.

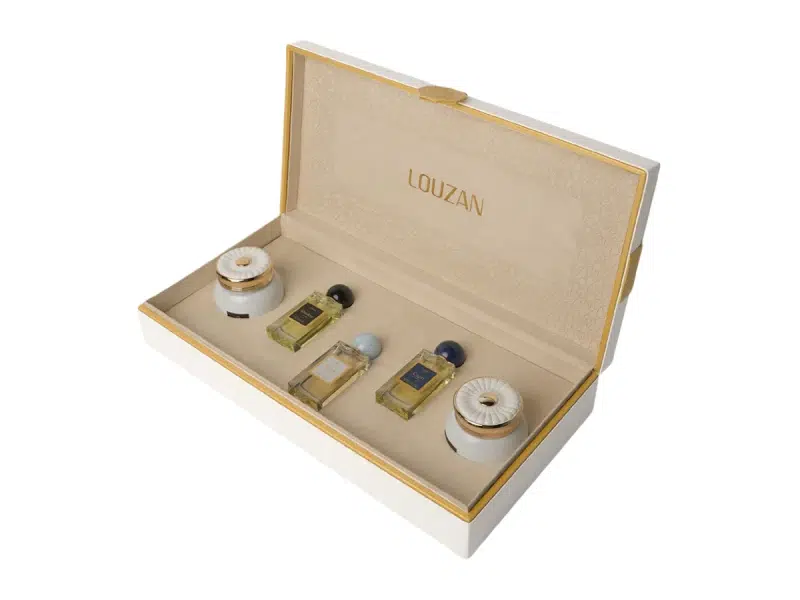

Ao longo dos anos, ajudei clientes a criar embalagens de perfume topo de gama com cavidades complexas para frascos, tampas e acessórios. O desafio é sempre o mesmo: como manter todas as curvas, entalhes e ângulos com um aspeto suave e sem falhas. Eis como o fazemos.

Porque é que o couro PU é uma escolha popular para interiores de caixas de perfume de luxo?

O couro PU é amplamente utilizado em embalagens de alta qualidade porque oferece:

- A sensação tátil de luxo1 que imita o couro verdadeiro

- Durabilidade com resistência às manchas e aos riscos

- Uma variedade de texturas e opções de cores para combinar com a marca

- Compatibilidade com espuma e madeira substratos

- A rentável alternativa ao couro genuíno

| Caraterística | Desempenho do couro PU |

|---|---|

| Apelo visual | ★★★★★ |

| Consistência da textura | ★★★★☆ |

| Flexibilidade | ★★★★☆ |

| Eficiência de custos | ★★★★★ |

Para a maioria das caixas de perfume, o couro PU oferece a melhor combinação de aparência, preço e consistência de produção.

Quais são os desafios de envolver formas complexas e recortes de forma limpa?

Quanto mais complexa for a forma interior, maior é o risco de:

- Rugas e dobras2 em cantos apertados

- Bolhas de ar3 em zonas côncavas

- Lacunas ou alongamentos à volta dos bordos

- Costuras visíveis4 que perturbam o aspeto premium

Os problemas típicos de corte ocorrem à volta:

- Cavidades de gargalo de garrafa

- Arestas de inserção arredondadas

- Tabuleiros rasos com cantos interiores afiados

| Área de desafio | Problema comum |

|---|---|

| Cantos interiores | Rugas ou lacunas |

| Recortes curvos | Alongamento excessivo |

| Bordos e lábios | Desgaste ou desalinhamento |

| Camadas complexas | Costuras irregulares |

Com cavidades complexas, cada milímetro de couro tem de ser tido em conta no processo de corte e enrolamento.

Como é que se preparam as inserções de espuma ou de madeira para garantir uma aplicação suave do couro?

A preparação adequada é fundamental. Quer esteja a embrulhar:

- Espuma EVA5

- Cartão rígido

- Inserções em MDF ou contraplacado6

O núcleo deve ser:

- Corte preciso de acordo com as especificações do projeto

- Sem pó ou detritos

- Ligeiramente lixado (para madeira) para remover arestas vivas

- Chanfrado ou arredondado nos bordos para reduzir o esforço de dobragem

Passos de preparação que recomendo:

- Utilização moldes de corte a laser7 para tolerâncias apertadas

- Preparar a madeira ou a espuma com vedante adesivo, se necessário

- Testar o revestimento de couro PU antes de colar

Os cantos arredondados são mais fáceis de embrulhar e resultam num acabamento mais limpo e de qualidade superior.

Que adesivos e ferramentas ajudam a evitar rugas, bolhas ou descamação ao longo do tempo?

Nem todas as colas funcionam com o couro PU. É necessário:

- Cimento de contacto (à base de solventes)8 para uma forte aderência

- Adesivos PU de base aquosa9 para aplicações mais amigas do ambiente

- Película de transferência térmica de dupla face10 para embalamento de máquinas de alta precisão

Ferramentas essenciais:

- Rolos de borracha macia - para alisar uniformemente a superfície

- Ferramentas de dobragem de bordos - para apertar o couro em cantos apertados

- Pistolas de calor - para aquecer suavemente o couro PU e aumentar a flexibilidade

- Espátulas de ponta de agulha - para pressionar material profundamente em ranhuras afiadas

| Etapa de aplicação | Ferramenta recomendada |

|---|---|

| Envolvimento amplo da superfície | Adesivo de rolo + pincel |

| Prensa de borda afiada | Espátula de borda |

| Contorno do recorte interior | Pistola de calor + prensa manual |

| Libertação de bolhas de ar | Ferramenta de cavilhas + prensar de novo |

Nunca apressar o tempo de colocação do adesivo.O couro PU necessita de um tempo de secagem ou de pressão adequado para não ter rugas a longo prazo.

Como é que se pode alcançar cantos afiados11 e arestas sem costuras12 em espaços apertados?

É aqui que o artesanato se encontra com a engenharia. Para cantos limpos:

- Linhas de dobragem pré-pontuação no couro (laser ou faca)

- Fazer cortes de precisão em relevo13 no suporte de couro

- Utilizar fita de borda para manter as camadas no lugar antes da prensagem final

- Arestas de camadas numa única direção para evitar a formação de cachos

- Para cavidades arredondadas, utilizar calor e tensão lenta alongamento

Dicas de embrulho por área:

| Caraterística da caixa | Técnica |

|---|---|

| Compartimentos quadrados | Cantos em esquadria + dobragem de bordos sobrepostos |

| Poços redondos para garrafas | Enrolar o PU à volta do raio, cortar o excesso |

| Tabuleiros com várias profundidades | Envolver em camadas, da mais profunda para a mais externa |

| Costuras da tampa articulada | Pré-dobragem com núcleo macio, enrolar firmemente |

O objetivo é tornar as costuras invisíveis - não apenas escondidas. Mesmo sob uma inspeção atenta, o acabamento deve parecer contínua e adaptada.

Que controlos de qualidade garantem um acabamento consistente e de alta qualidade em toda a produção?

Seguimos sempre um rigoroso processo de controlo de qualidade14 para caixas revestidas a couro. Principais pontos de controlo:

- Inspeção visual sob luz angular para detetar ondas ou rugas à superfície

- Teste de pressão dos dedos em zonas de grande tensão (cantos, arestas)

- Ensaio de tração de aderência15 nos rebordos dos recortes após 24h de cura

- Verificação da consistência da cor sob iluminação normalizada (D65)

- Simulação de unboxing do cliente16 para avaliar o impacto da apresentação

| Teste QC | Objetivo |

|---|---|

| Varrimento visual | Apanhar defeitos nos bordos, marcas de cola |

| Ensaio de aderência | Evitar a descamação ou o empeno |

| Teste tátil | Assegurar um toque suave e luxuoso |

| Controlo da durabilidade | Simular o desgaste |

A revisão final inclui o alinhamento da espuma, a tensão do couro e a uniformidade da costura - especialmente em caixas de perfume de alta qualidade, onde apresentação = valor do produto.

Conclusão

Envolver couro PU em torno de recortes internos complexos é parte arte, parte engenharia.

Para obter um resultado limpo e de alta qualidade:

- Preparar o material de base com uma geometria limpa e arredondada

- Utilizar colas adaptadas ao couro PU e a superfícies curvas

- Confie nas ferramentas manuais, no calor e no enrolamento em camadas para obter bordos perfeitos

- Testar, inspecionar e ajustar - especialmente para clientes de embalagens de qualidade superior

Porque quando se trata de caixas de perfumes de luxo, todos os pormenores do interior são tão importantes como os do exterior.

Nome da marca: WoodoBox

Slogan: Caixas de madeira personalizadas, fabricadas na perfeição

Sítio Web: www.woodobox.com

-

Descubra como a luxuosa sensação tátil do couro PU melhora a experiência geral das embalagens de luxo. ↩

-

Compreender as causas das rugas e dobras pode ajudar a melhorar as suas técnicas de enrolamento e a obter um acabamento impecável. ↩

-

A prevenção de bolhas de ar é crucial para uma aparência suave e profissional; explore técnicas eficazes para evitar este problema comum. ↩

-

Aprender as melhores práticas para evitar costuras visíveis pode melhorar a estética geral dos seus produtos embalados, dando-lhes um aspeto mais premium. ↩

-

Explore esta ligação para compreender as propriedades da espuma EVA e as suas vantagens nas aplicações em couro, garantindo um acabamento suave. ↩

-

Saiba mais sobre as vantagens da utilização de inserções de MDF ou contraplacado na embalagem de couro para um aspeto profissional e durabilidade. ↩

-

Descubra como as matrizes de corte a laser aumentam a precisão no empacotamento de couro, levando a melhores resultados e menos desperdício. ↩

-

Explore esta ligação para compreender as propriedades e aplicações do cimento de contacto para uma adesão óptima ao couro PU. ↩

-

Descubra as vantagens das colas PU ecológicas de base aquosa e como podem melhorar os seus projectos. ↩

-

Saiba mais sobre a eficácia da película de transferência térmica de dupla face na obtenção de embalagens de alta precisão sem bolhas ou rugas. ↩

-

Explore técnicas para obter cantos afiados na confeção de peles para melhorar a qualidade e a estética dos seus projectos. ↩

-

Aprenda sobre métodos eficazes para criar bordos sem costuras em trabalhos em pele para elevar a sua habilidade e acabamento. ↩

-

Descubra a importância dos cortes de precisão em relevo na confeção de peles para obter resultados limpos e profissionais. ↩

-

Compreender o processo de controlo de qualidade pode ajudá-lo a garantir padrões elevados na produção, conduzindo a melhores produtos. ↩

-

Saiba mais sobre o teste de tração de aderência para compreender o seu papel na prevenção de defeitos do produto e na garantia da durabilidade. ↩

-

Explore a forma como as simulações de unboxing do cliente melhoram a apresentação do produto e a satisfação do cliente, crucial para os artigos de luxo. ↩