Le scatole di legno riutilizzabili richiedono più che un semplice aspetto estetico. Senza resistenza strutturale e materiali durevoli, si rompono rapidamente.

Per garantire la riutilizzabilità, i produttori devono rinforzare la struttura, selezionare legno resistente, utilizzare ferramenta robusta, applicare finiture protettive e bilanciare l'eco-compatibilità con la longevità.

Progettare per un uso ripetuto significa pensare oltre la prima impressione.

Quali rinforzi strutturali sono necessari per garantire aperture e chiusure ripetute?

Ogni apertura sottopone la scatola a sollecitazioni. Le strutture deboli si consumano rapidamente.

Rinforzi quali giunti resistenti, pareti più spesse e rapporti di copertura testati garantiscono che la scatola resista a un uso ripetuto.

Le pareti sottili o i giunti deboli possono resistere una volta, ma dopo 50 aperture cedono. Rinforzare significa costruire con metodi strutturali collaudati che proteggono sia la bellezza che la funzionalità.

Metodi di rinforzo strutturale

- Utilizzare giunti a incastro o a coda di rondine per ottenere bordi più resistenti.

- Aumentare lo spessore delle pareti dei coperchi e delle basi.

- Applicare blocchi angolari interni per una maggiore stabilità.

- Mantenere rapporti standard tra coperchio e base per garantire l'equilibrio.

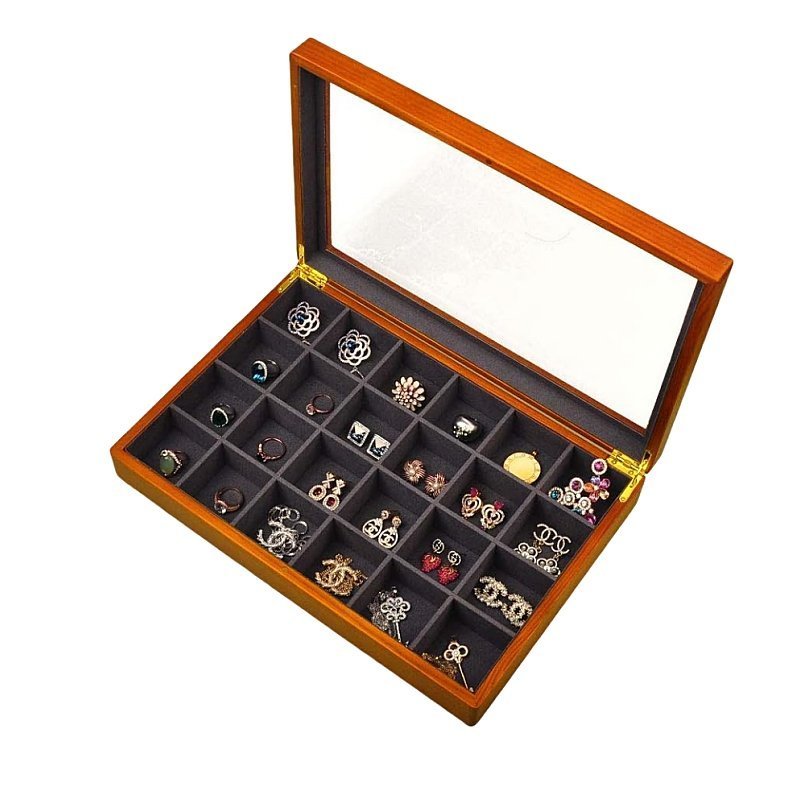

Una volta ho realizzato un progetto per una scatola portagioie in cui il cliente inizialmente aveva richiesto pannelli laterali molto sottili per risparmiare sui costi. Dopo i test, il coperchio si è deformato nel giro di poche settimane. Abbiamo quindi optato per un MDF più spesso con impiallacciatura e abbiamo aggiunto giunti rinforzati. La scatola ha poi superato ripetuti test di resistenza.

Come scegliere il tipo di legno giusto per garantire durata e resistenza a lungo termine?

Non tutti i tipi di legno resistono bene all'uso ripetuto. Alcuni hanno un bell'aspetto ma non sono abbastanza resistenti.

Per quanto riguarda la durata, i legni duri o il legno ingegnerizzato con impiallacciatura di qualità offrono prestazioni migliori rispetto al legno tenero o alle opzioni instabili.

I legni duri massicci come il mogano o la quercia resistono agli urti e all'usura. Il MDF con impiallacciatura offre stabilità contro le deformazioni. Il pino o il compensato, più economici, possono rompersi sotto pressione.

Scelta del legno per scatole riutilizzabili

| Tipo di legno | Durata | Miglior utilizzo |

|---|---|---|

| Mogano | Molto forte | Scatole riutilizzabili di lusso |

| Quercia | Duro e stabile | Scatole di stoccaggio premium |

| MDF + impiallacciatura | Conveniente | Scatole decorative riutilizzabili |

| Pino/Compensato | Debole, instabile | Non idoneo al riutilizzo |

Per un progetto relativo a scatole per sigari in Germania, il cliente aveva inizialmente scelto il compensato per motivi di costo. Dopo un test di resistenza, abbiamo consigliato il cedro spagnolo con rinforzo in MDF. Questa combinazione ha preservato sia la struttura che le prestazioni aromatiche, dimostrando che la scelta dei materiali è fondamentale.

Perché cerniere, serrature e giunti svolgono un ruolo fondamentale nelle scatole di legno multiuso?

L'hardware è la parte più sollecitata di qualsiasi scatola riutilizzabile. Scelte sbagliate causano guasti prematuri.

Cerniere robuste, serrature affidabili e giunti rinforzati sono essenziali per garantire un funzionamento regolare e una lunga durata nel tempo.

Ogni apertura sollecita i cardini. Ogni chiusura sollecita serrature e giunti. Senza ferramenta resistente, le scatole si rompono rapidamente, indipendentemente dalla bellezza dell'aspetto esteriore.

Standard hardware

- Cerniere: Utilizzare cerniere in ottone o acciaio inossidabile con chiusura ammortizzata.

- Serrature: Scegliete chiusure resistenti o sistemi magnetici testati per cicli ripetuti.

- Giunti: Utilizzare giunti a coda di rondine, giunti a pettine o giunti rinforzati per garantire la resistenza alle sollecitazioni.

Un ordine di scatole per orologi per un marchio mediorientale è fallito perché sono state utilizzate cerniere in ferro di bassa qualità. Dopo sei mesi, molti clienti si sono lamentati della ruggine e dei coperchi rotti. Le abbiamo sostituite con cerniere in acciaio inossidabile, risolvendo il problema. La ferramenta determina la qualità a lungo termine.

In che modo i materiali di rivestimento interno (velluto, pelle, tessuto) possono influire sulla durata e sulla riutilizzabilità?

Gli interni sono soggetti a usura a causa del contatto costante con i prodotti. I materiali non adeguati si consumano rapidamente.

I rivestimenti interni devono resistere all'attrito, all'umidità e alle ripetute manipolazioni per garantire un utilizzo a lungo termine.

Il velluto è morbido al tatto, ma quello di scarsa qualità si consuma con il tempo. La pelle PU è resistente, ma può screpolarsi se esposta all'umidità. La pelle scamosciata naturale ha un aspetto lussuoso, ma è sensibile all'umidità.

Opzioni di rivestimento per scatole riutilizzabili

| Materiale della fodera | Vantaggio | Limitazione |

|---|---|---|

| Velluto di alta qualità | Look morbido ed elegante | Si consuma in caso di forte attrito |

| Pelle PU | Resistente, facile da pulire | Può invecchiare in climi umidi |

| Pelle scamosciata naturale | Lussuoso, di alta qualità | Sensibile all'umidità |

| Tessuto intrecciato | Traspirante, stabile | Sensazione meno lussuosa |

Una volta ho realizzato una serie di portagioie riutilizzabili con velluto a basso costo. Dopo un anno, i clienti hanno notato che il velluto si stava consumando. Nella serie successiva, abbiamo sostituito il rivestimento interno con pelle PU. Il feedback è migliorato notevolmente, dimostrando come le scelte relative agli interni influiscano sulla riutilizzabilità.

Quali metodi di finitura e rivestimento aiutano a proteggere la scatola dall'usura, dall'umidità e dai graffi?

Senza una finitura resistente, anche il legno migliore perde qualità dopo un uso ripetuto.

Le finiture protettive come la vernice, il PU e gli oli naturali prolungano la durata delle scatole di legno riutilizzabili.

La vernice lucida a specchio è resistente ai graffi e all'umidità. Le finiture opache in PU offrono una durata discreta. Gli oli naturali proteggono le venature del legno, ma richiedono manutenzione.

Opzioni di rivestimento protettivo

- Lacca per pianoforte: Lussuoso, altamente resistente, ma laborioso.

- PU opaco: Resistente ai graffi, conveniente.

- Oli naturali: Ecologico, richiede una riapplicazione.

- Rivestimento UV: Previene lo sbiadimento, adatto per scatole decorative.

Un ordine di scatole per vino per un cliente britannico richiedeva un'elevata riutilizzabilità. Abbiamo utilizzato 12 strati di vernice lucida con lucidatura a mano. La finitura non solo aveva un aspetto pregiato, ma è rimasta priva di graffi anche dopo anni di uso ripetuto.

Come bilanciare l'eco-compatibilità con la durata quando si progetta per usi multipli?

Oggi i clienti hanno a cuore la sostenibilità. Ma eco-compatibile deve anche significare durevole.

Conciliare l'eco-compatibilità con la durata significa scegliere legno sostenibile, finiture a basso contenuto di COV e ferramenta riciclabile, garantendo al contempo la resistenza strutturale.

L'uso di legno certificato FSC, finiture a base d'acqua e componenti riciclabili riduce l'impatto ambientale. Tuttavia, evitare rinforzi strutturali in nome dell'eco-compatibilità può rendere la scatola usa e getta, il che non è veramente sostenibile.

Scelte ecologiche equilibrate

- Mogano o cedro certificato FSC.

- Finiture PU a base acquosa.

- Hardware in acciaio inossidabile riciclabile.

- Design di lunga durata che evita gli sprechi legati alla sostituzione.

Una volta ho fornito consulenza a un marchio scandinavo che desiderava un “imballaggio ecologico”. Invece di rimuovere i rivestimenti protettivi, abbiamo utilizzato vernici a base d'acqua e impiallacciature rinnovabili. Le scatole sono durate anni e i clienti hanno apprezzato sia la loro resistenza che i valori ecologici.

Conclusione

Le scatole di legno riutilizzabili richiedono scelte oculate dei materiali, ferramenta resistente, finiture protettive e una durata eco-compatibile per garantire un valore reale a lungo termine.

Nome del marchio: WoodoBox

Slogan: Scatole di legno personalizzate, realizzate alla perfezione

Sito web: www.woodobox.com

WhatsApp: +86 18359265311