L'allocazione del budget nella personalizzazione delle scatole di legno spesso confonde i clienti perché ogni opzione sembra importante.

Il modo più veloce per decidere è dare priorità prima alla struttura, poi alle finiture e infine ai materiali, adeguandosi al posizionamento del marchio e agli obiettivi del cliente.

Priorità chiare riducono la confusione, accelerano il processo decisionale e impediscono spese eccessive per dettagli non essenziali.

Una scatola bella ma con una struttura scadente è inutile.

La stabilità strutturale e la funzionalità devono avere la priorità nel budget perché determinano l'usabilità, la durata e la soddisfazione complessiva del cliente.

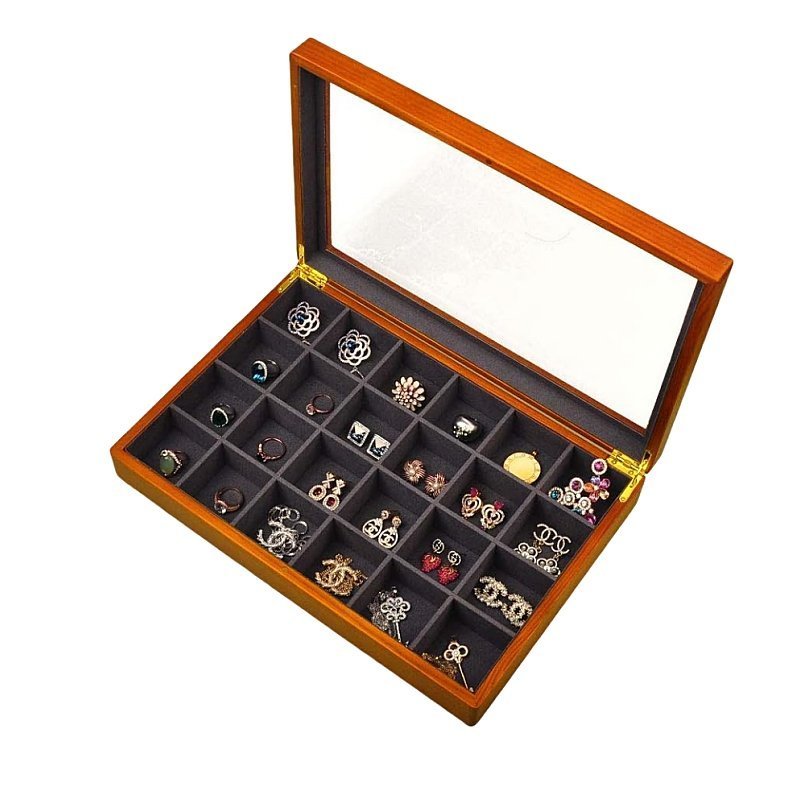

Consiglio sempre ai clienti di iniziare dalla struttura. Se la scatola non si apre facilmente, non si allinea correttamente o non protegge il prodotto al suo interno, la finitura e la scelta dei materiali non possono compensare questi difetti. Una scatola di sigari che non si chiude bene o un portagioie con una cerniera allentata diventano un problema per il marchio. I difetti strutturali sono la prima cosa che i clienti notano.

Ricordo un caso relativo a un progetto di scatola per orologi in cui il marchio si era concentrato sull'impiallacciatura esotica prima di confermare la struttura interna. Dopo i prototipi, ci siamo resi conto che le dimensioni del cuscino erano troppo piccole per orologi più grandi. Tutta la costosa impiallacciatura è andata sprecata perché la struttura non è riuscita a svolgere la sua funzione. Questo errore ha rafforzato la mia convinzione che il budget debba dare priorità alla struttura.

Priorità strutturali fondamentali

- Allineamento del coperchio e resistenza della cerniera

- Dimensioni degli scomparti interni

- Stabilità durante la movimentazione e il trasporto

- Protezione di oggetti delicati

Spendere qui garantisce che la scatola funzioni come previsto. Solo dopo aver assicurato questa base si dovrebbe prendere in considerazione la finitura e i materiali.

In che modo le tecniche di finitura (laccatura, intarsio, incisione) possono aumentare il valore percepito con un costo moderato?

La finitura è ciò che i clienti percepiscono come lusso.

Le tecniche di finitura come la laccatura, l'intarsio o l'incisione aumentano notevolmente il valore percepito, spesso a un costo moderato rispetto ai materiali.

Una volta che la struttura è solida, l'attenzione si concentra sulle finiture. I clienti associano lucentezza, levigatezza e dettagli artistici al lusso. Una finitura laccata o intarsi in metallo comunicano immediatamente valore. Il vantaggio è che queste tecniche spesso costano meno rispetto all'utilizzo di materiali di qualità superiore. Ad esempio, una semplice scatola con anima in MDF può sembrare di alta qualità con più strati di lacca, mentre il legno massello con finiture scadenti sembra economico.

Ho lavorato con un marchio di sigari che voleva un prodotto di alta gamma ma aveva un budget limitato. Invece del palissandro massiccio, abbiamo utilizzato MDF impiallacciato e investito maggiormente in 12 strati di vernice lucida e stampa a caldo dorata. Il risultato finale era lussuoso e il marchio ha risparmiato 30% sui costi. La finitura ha permesso loro di competere con prodotti più costosi senza spendere troppo.

Opzioni di finitura ed effetti

| Tecnica | Effetto sulla percezione del valore | Livello di costo |

|---|---|---|

| Lacca ad alta lucentezza | Lusso, superficie riflettente | Medio |

| Intarsio di impiallacciatura | Eleganza naturale, esclusività | Medio-alto |

| Incisione/Stampaggio | Branding, personalizzazione | Medio-basso |

| Texture opaca | Stile moderno e sobrio | Medio |

La finitura è il “gancio visivo”. Crea la prima impressione che convince gli acquirenti della qualità.

Che ruolo gioca la scelta dei materiali (legno massello, impiallacciatura, opzioni ecologiche) nel bilanciare lusso e budget?

I materiali raccontano una storia di autenticità e sostenibilità.

La scelta dei materiali definisce le caratteristiche fondamentali della scatola, ma deve essere equilibrata tra lusso, resistenza e convenienza economica.

Mentre la struttura riguarda la funzionalità e le finiture riguardano la percezione, i materiali aggiungono credibilità. Il legno massello trasmette autenticità, mentre le impiallacciature offrono flessibilità a un costo inferiore. I materiali ecologici attraggono gli acquirenti moderni attenti alla sostenibilità. La chiave non è sempre scegliere il legno più costoso, ma abbinare la scelta dei materiali alla storia del marchio del cliente.

Una volta ho lavorato a un progetto di scatole per vino per un marchio premium ma attento all'ambiente. Invece del mogano, abbiamo scelto un rivestimento in betulla certificato FSC. Abbinate a una finitura opaca, le scatole avevano un aspetto elegante ma in linea con gli obiettivi di sostenibilità del marchio. I clienti del committente hanno apprezzato il messaggio eco-friendly tanto quanto il prodotto stesso.

Confronto tra i materiali

| Materiale | Pro | Contro | Costo |

|---|---|---|---|

| Legno massiccio | Premium, resistente, autentico | Costoso, pesante, meno flessibile | Alto |

| Impiallacciatura + MDF | Conveniente, ampia scelta di design | Meno “autentico” | Medio |

| Pannello ecologico | Sostenibile, attraente per i consumatori | Finiture limitate, durata variabile | Medio-basso |

Bilanciando la scelta dei materiali con il budget, garantiamo sia un appeal di lusso che una gestione pratica dei costi.

Come identificare quale elemento — struttura, finitura o materiale — si adatta meglio al posizionamento del marchio?

Non tutti i marchi attribuiscono la stessa importanza alle stesse priorità.

Identificare la giusta priorità dipende dall'immagine del marchio: i marchi di lusso puntano sulle finiture e sui materiali, mentre quelli più pratici si concentrano maggiormente sulla struttura.

Mercati diversi danno importanza a aspetti diversi. Un marchio di sigari rivolto ai collezionisti potrebbe richiedere un rivestimento in legno raro. Un marchio di gioielli potrebbe dare importanza a una finitura lucida che rifletta il lusso. Un marchio di vini che spedisce in tutto il mondo potrebbe concentrarsi sulla struttura per garantire la protezione durante il trasporto. Comprendere il posizionamento del marchio ci aiuta a orientare l'allocazione del budget.

Allineare le priorità al posizionamento del marchio

| Tipo di marchio | Priorità |

|---|---|

| Marchio ultra-lusso | Materiale + Finitura |

| Premium di fascia media | Struttura + Finitura |

| Marchio eco-consapevole | Materiale + Struttura |

| Marchio pratico per la vendita al dettaglio | Prima la struttura |

Chiedo sempre ai clienti di descrivere la loro identità fondamentale: “Volete che la vostra scatola sia esclusiva, sostenibile o affidabile?” La risposta determina dove destinare la maggior parte del budget.

Perché è efficace stilare una lista di priorità “indispensabili vs. auspicabili” per garantire la chiarezza del budget?

I clienti spesso vogliono tutto, ma non tutto rientra nel budget.

Creare un elenco di elementi indispensabili e di elementi auspicabili impone una chiara allocazione del budget, evitando confusione e aggiornamenti non necessari.

Aiuto i clienti a dividere le caratteristiche in due categorie. Quelle indispensabili non sono negoziabili: struttura robusta, cerniere scorrevoli, logo del marchio. Quelle auspicabili sono opzionali: rivestimento in lamina d'oro, legno esotico, intarsi complessi. Scrivendo insieme questo elenco, il cliente capisce dove investire prima il budget. In questo modo si evitano infinite discussioni quando i costi aumentano.

Esempio di elenco delle priorità per un portagioie

- Indispensabile: Struttura stabile, fodera in velluto perfetta, logo stampato a caldo ben visibile.

- Bello da avere: Impiallacciatura esotica, cerniera placcata in oro, incisione sul coperchio.

Questo esercizio rende più veloce il processo decisionale. I clienti si sentono in controllo e i fornitori evitano di sprecare risorse.

In che modo una ripartizione trasparente dei costi può aiutare i clienti a prendere decisioni più rapide e sicure?

I costi nascosti causano ritardi e sfiducia.

Una ripartizione trasparente dei costi consente ai clienti di vedere dove vanno a finire i loro soldi, aiutandoli a decidere in modo rapido e sicuro sui compromessi da accettare.

Fornisco sempre preventivi dettagliati che separano i costi di struttura, finitura e materiali. Ad esempio, invece di “scatola di legno: $20”, indico “struttura: $8, finitura: $7, materiale: $5”. Questa trasparenza mostra ai clienti come gli aggiornamenti influiscono sul prezzo. Se desiderano aggiungere altri 5 strati di vernice, possono vedere l'esatto impatto sui costi.

Una volta ho lavorato con un marchio di profumi in cui l'acquirente aveva difficoltà a ottenere l'approvazione del budget internamente. Mostrando un foglio dei costi trasparente, hanno presentato un caso chiaro alla loro direzione: “Ecco dove va ogni dollaro”. L'approvazione è arrivata più rapidamente e il progetto è andato avanti senza intoppi.

Vantaggi della determinazione trasparente dei costi

- Chiarezza: I clienti comprendono i compromessi.

- Velocità: Le decisioni vengono prese più rapidamente.

- Fiducia: Gli acquirenti si sentono trattati in modo equo.

- Flessibilità: Facile da regolare senza confusione.

Questa pratica rafforza la fiducia e riduce i tempi di negoziazione, a vantaggio di entrambe le parti.

Conclusione

I clienti decidono più rapidamente i budget quando la struttura viene prima, la finitura seconda e il materiale ultimo, con adeguamenti basati sugli obiettivi del marchio e sulla trasparenza.

Nome del marchio: WoodoBox

Slogan: Scatole di legno personalizzate, realizzate alla perfezione

Sito web: www.woodobox.com

WhatsApp: +86 18359265311