Custom Boxes, Made Easy

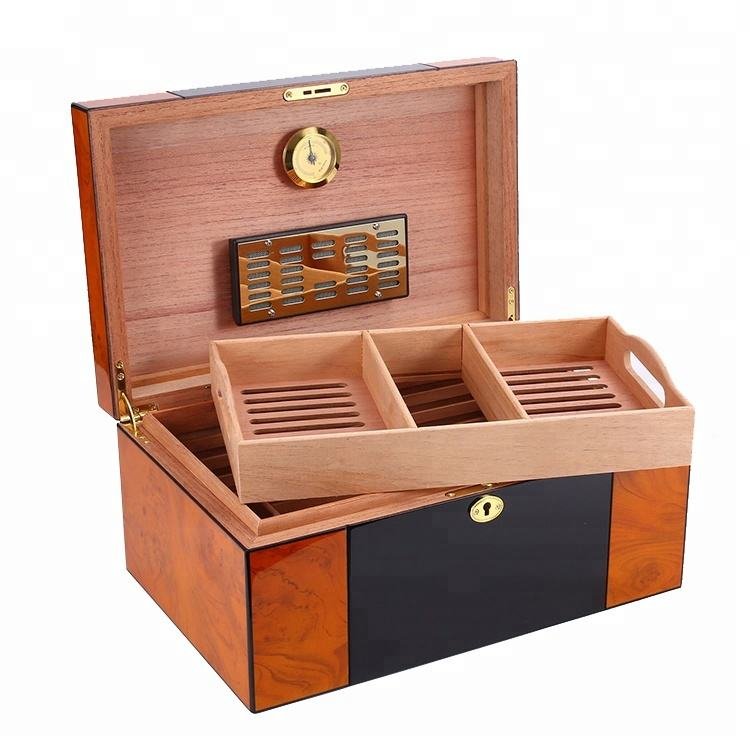

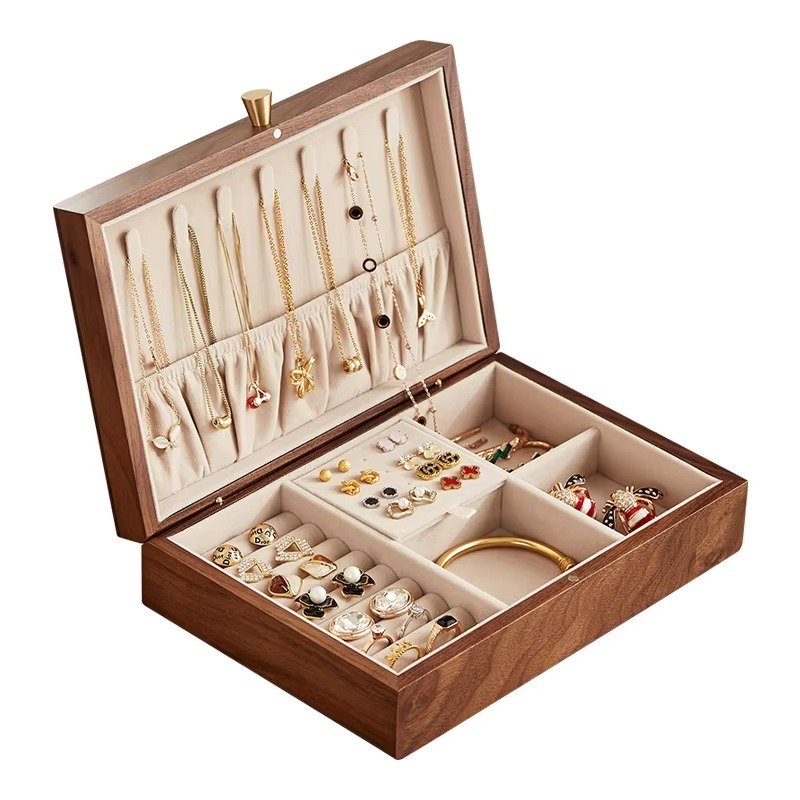

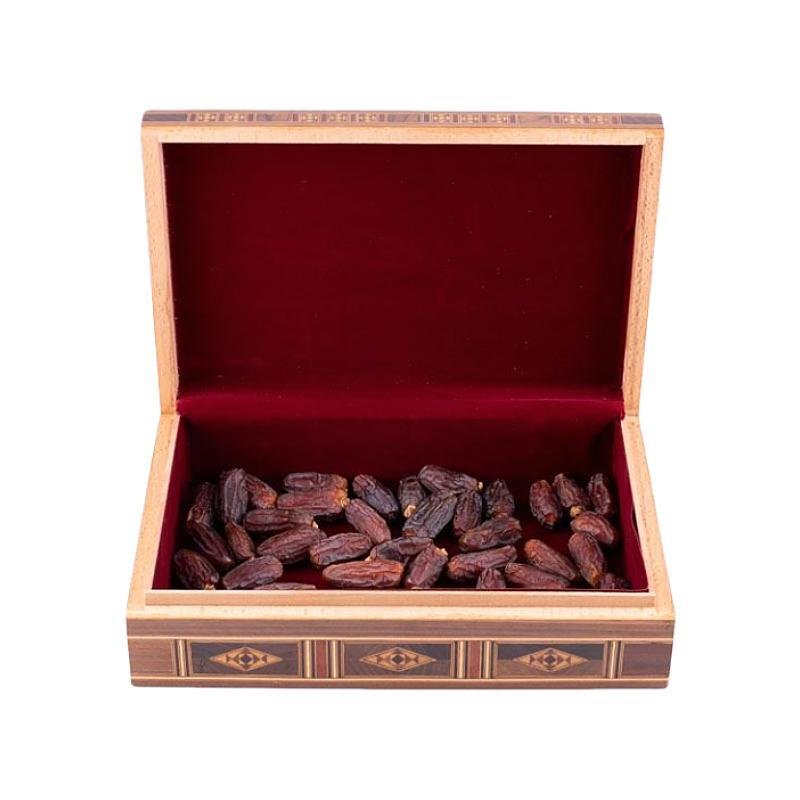

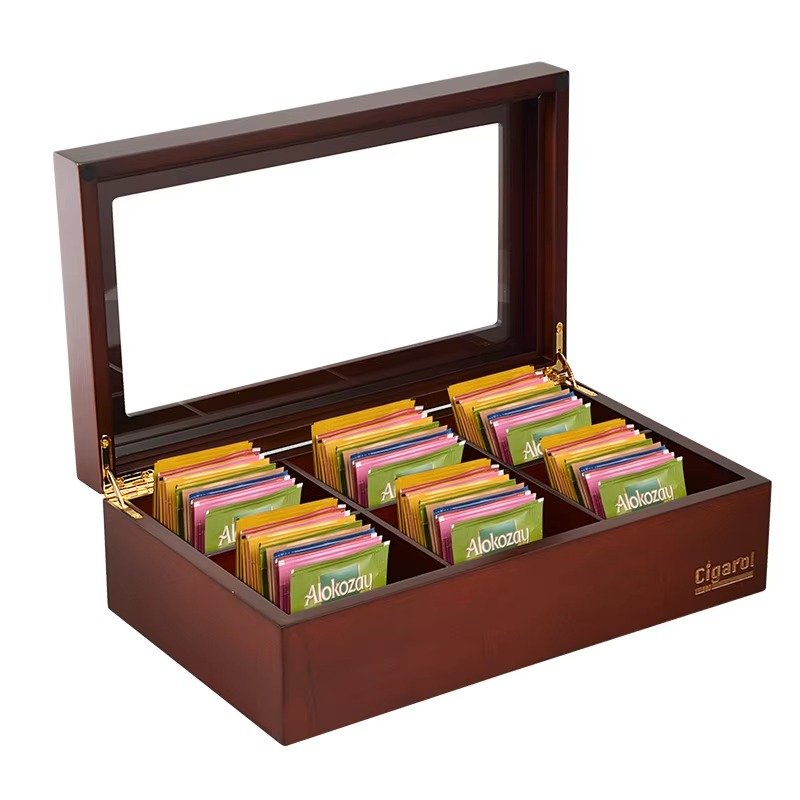

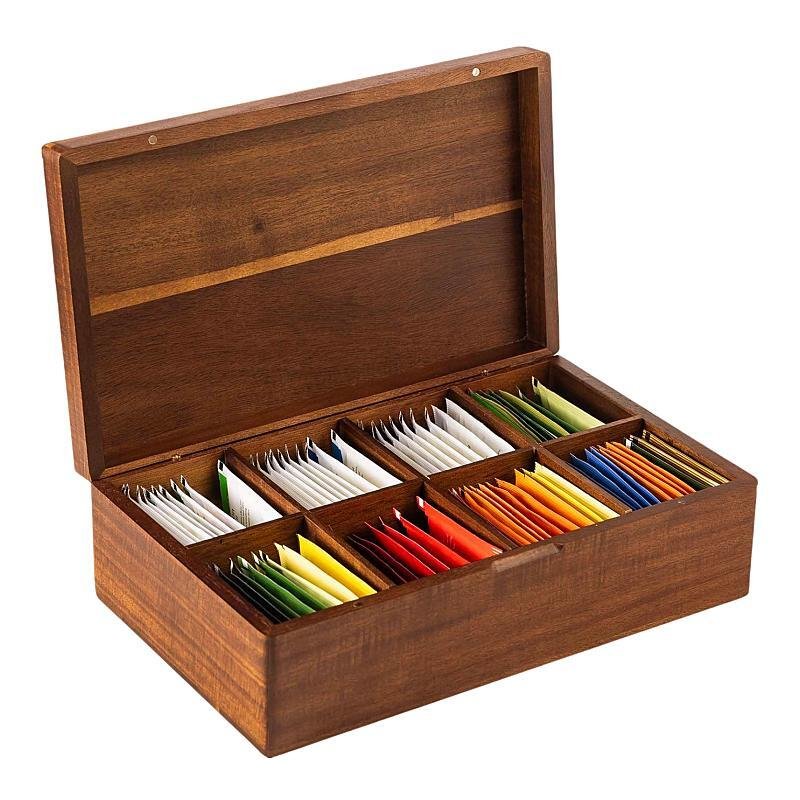

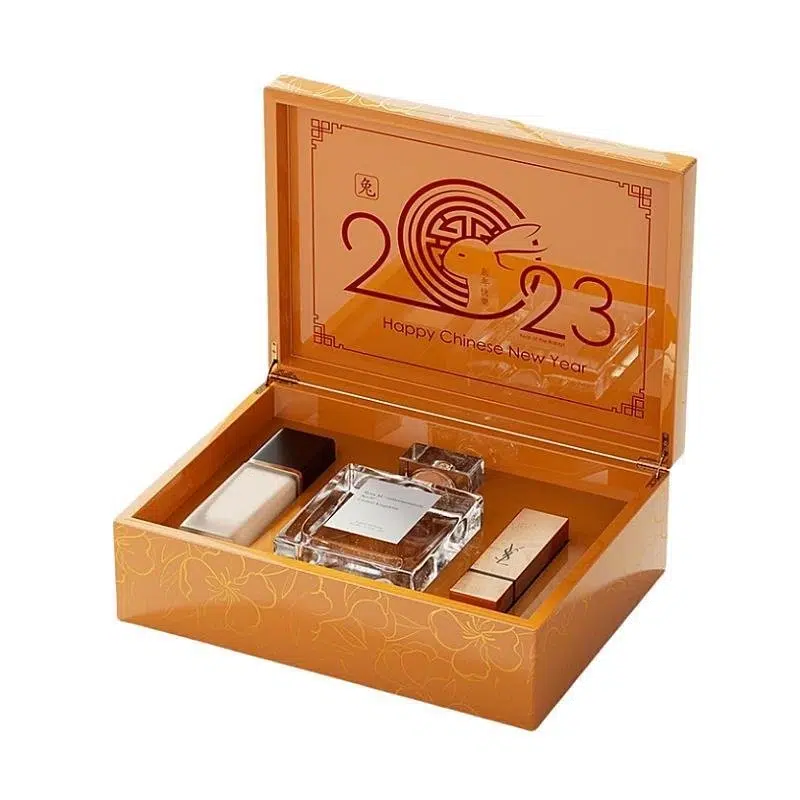

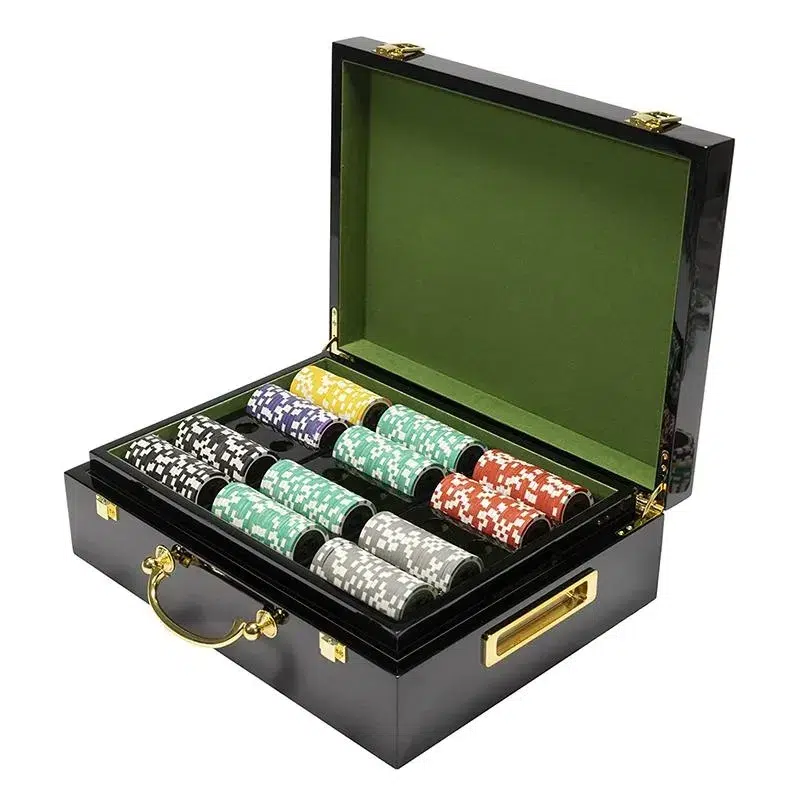

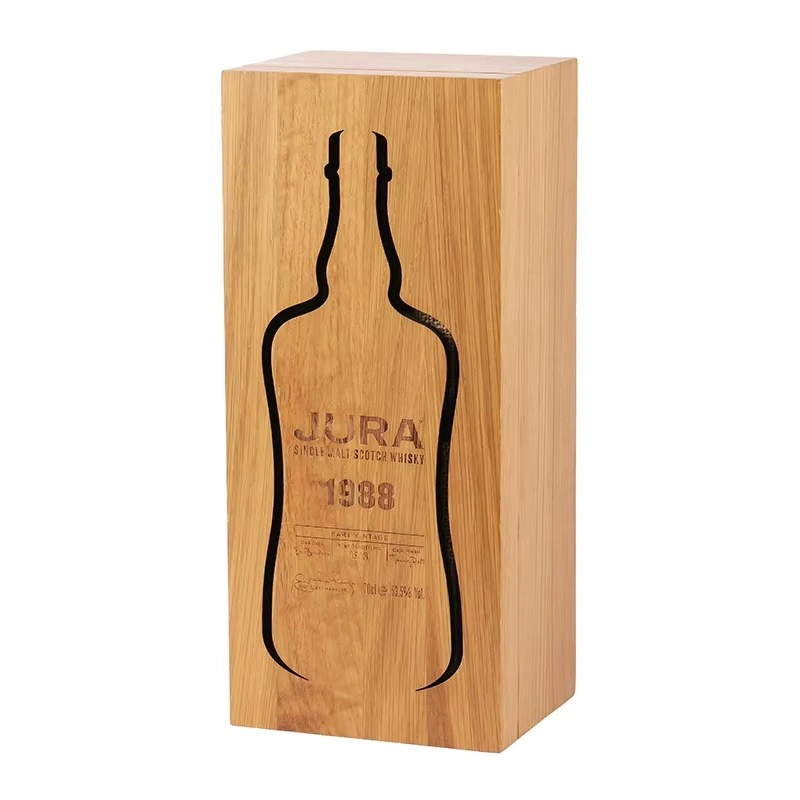

We make high-end boxes for cigars, jewelry, spirits, perfumes, and more—fully customized to your style.

From one sample to full production, we keep it simple, fast, and reliable.

OPTIONS & MATERIALS

Full Customization Solution For You

Custom wooden boxes are not just about size.

Box structure, materials, surface finish, hardware, and inserts all affect cost, appearance, and production stability.

Below are the customization options we use most often in real production projects.

Different box structures affect user experience, structure complexity, and cost.

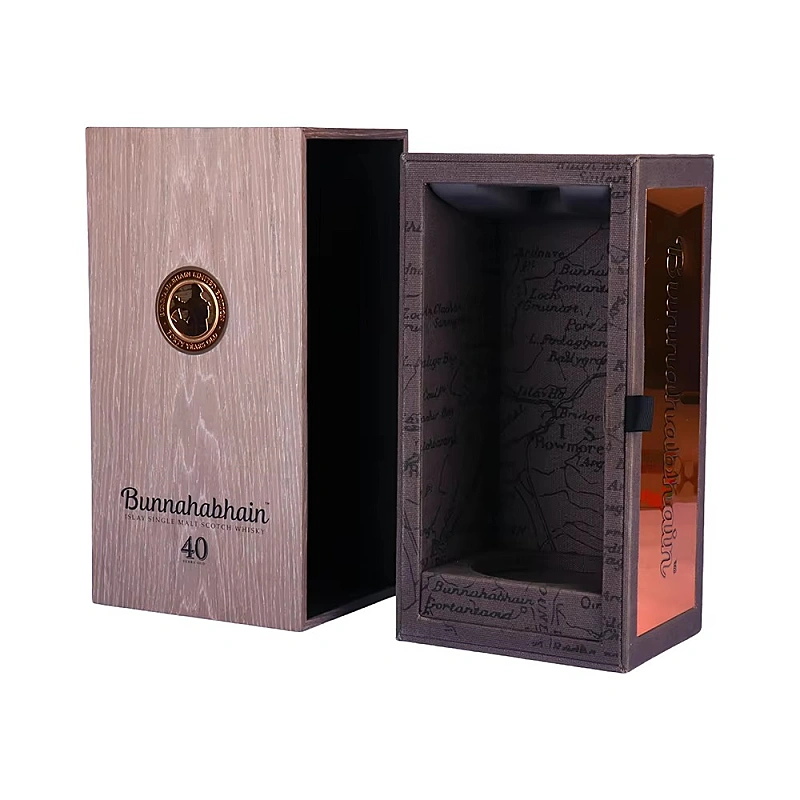

Hinged box

Most common, stable and suitable for most products

Sliding lid box

Simple structure, cost-effective

Lift-off lid box

Clean look, often used for gift boxes

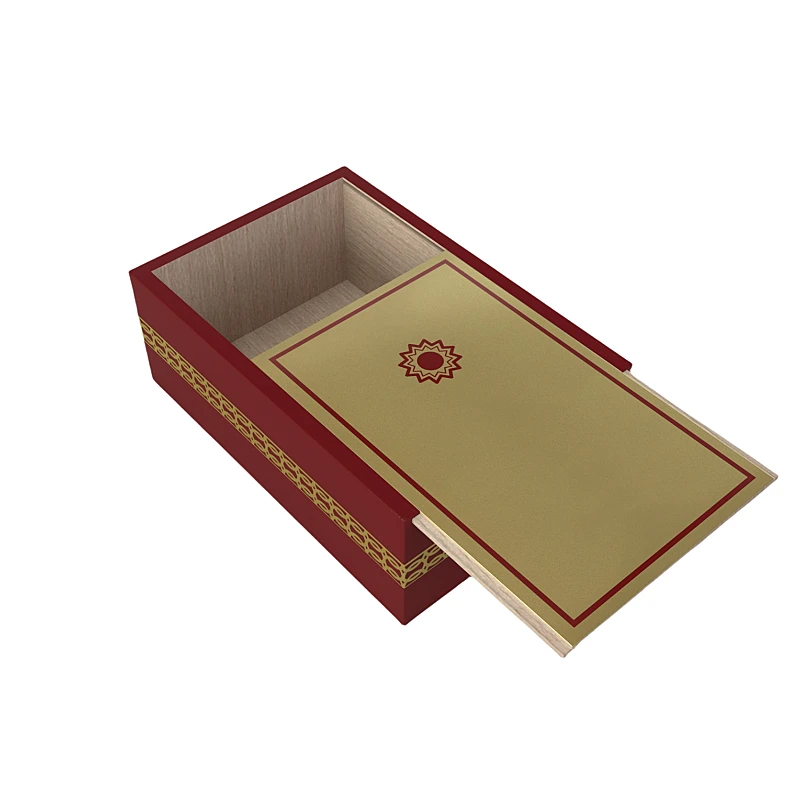

Drawer box

Strong presentation feel, higher structure requirements

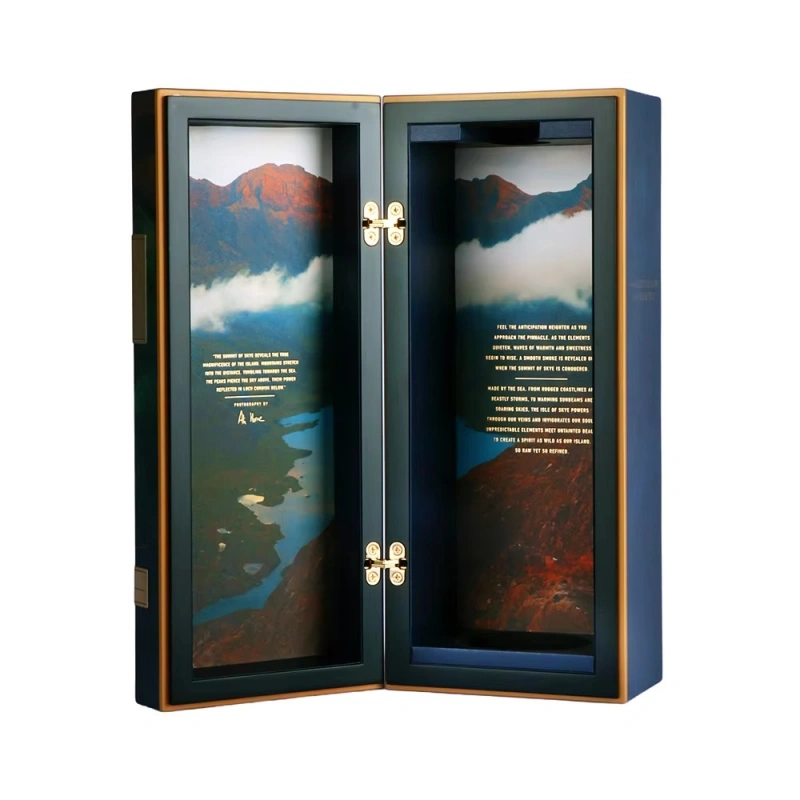

Double door box

Good display effect, higher hardware and structure requirements

Material choice affects stability, weight, and long-term consistency.

Legno massiccio

Best natural texture, but higher risk of movement

MDF

Most stable and best for mass production

Compensato

High strength, often used for structural parts

Bamboo wood

Natural grain appearance with good stability, eco-friendly

Lacquer finish affects appearance and rejection rate.

Piano finish

Mirror-like, highest requirements

High-gloss finish

Strong visual impact

Finitura opaca

More stable and easier to control

This is the first thing customers see.

Clear lacquer spray

Color lacquer spray

Natural wood veneer

Engineered veneer

Wood grain paper

PU leather wrapping

Logo details are small, but mistakes are very visible.

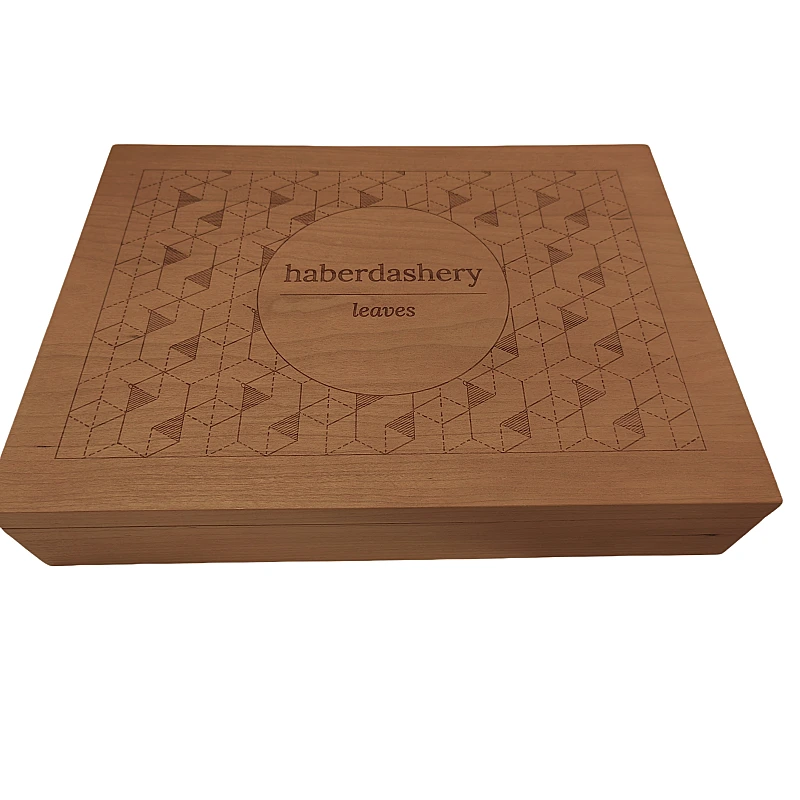

Hot stamping

Incisione laser

Stampa UV

Metal letters

Metal logo plates

Hardware affects both user experience and service life.

Concealed Hinge

Quadrant Hinge

Butterfly Hinge

Barrel Hinge

Push lock

Button lock

Horn lock

Custom locks

Metal feet

Decorative metal parts

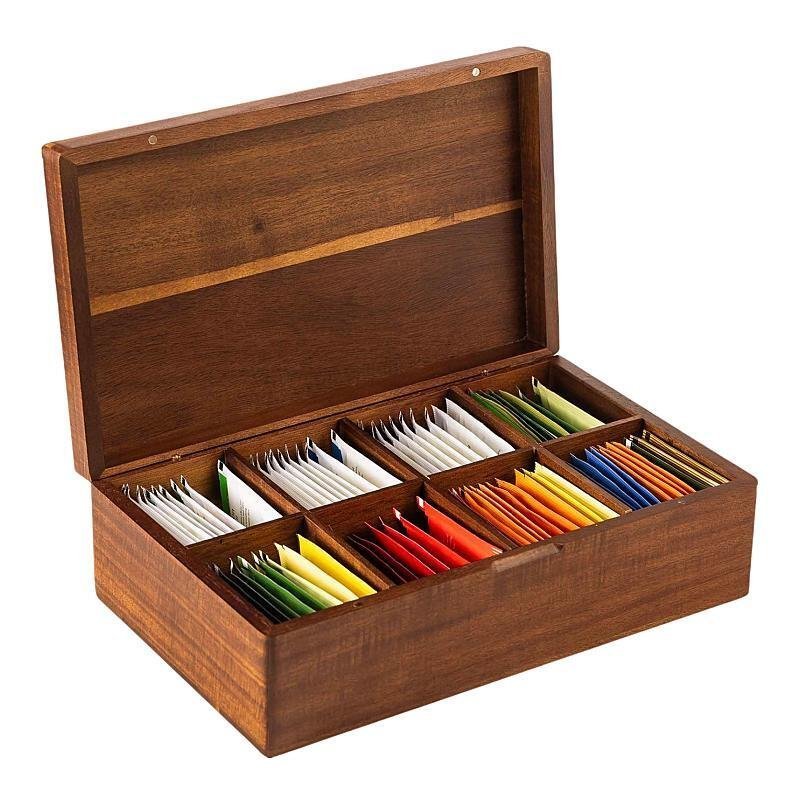

The purpose of inserts is protection, not decoration.

EPE foam

Schiuma EVA

Wooden inserts

PU leather lining

Fodera in velluto

Silk lining

Outer packaging affects transportation safety and presentation.

Standard packaging

Velvet pouch

Custom gift box

Before We Make the Box, We Decide These Things

Good custom projects are decided early, not fixed later.

Clear decisions reduce cost, delays, and rework.

01

Is a Wooden Box the Right Choice?

We first check if a wooden box fits your product, positioning, and budget.

02

Which Box Structure Is the Safest?

We help you choose a structure that works for weight, usage, and transport.

03

Which Material Works Best for Your Case?

Solid wood, MDF, or plywood — we explain the pros and risks clearly.

04

How Should the Surface Look and Feel?

Gloss, matte, veneer, leather — we focus on what looks good e stays stable.

05

How Should the Product Be Fixed Inside?

Inserts are chosen based on protection, not decoration.

06

Which Details Should Be Locked Before Sampling?

Size, logo method, hardware, and finish are confirmed before making samples.

07

Does the Sample Match Real Production?

The sample is checked for structure, finish, and consistency.

08

Is the Design Ready for Mass Production?

Only stable and repeatable designs move into bulk production.

Customization Process

We follow a clear process to make sure your custom box can be produced smoothly and consistently.

Share Your Idea

Tell us your product, size, quantity, and target use. Drawings are helpful, but not required.

Structure & Materials

We recommend suitable structure and materials based on stability, cost, and production feasibility.

Confirm Design Details

Box size, finish, logo method, hardware, and inserts are confirmed before sampling.

Campionamento

Samples are made for structure and appearance approval.

Produzione di massa

Production starts after sample approval.

Check & Shipping

We check key details and pack the goods based on the agreed packaging and shipping terms.

Delivery & MOQ

Lead Time

Campionamento

Sample lead time: 10–15 days

Depends on box structure, surface finish, and logo method

Produzione di massa

Production lead time: 35–50 days

Starts after sample approval

Minimum Order Quantity (MOQ)

Mid to High-End Custom Wooden Boxes

MOQ: 300 pcs

Suitable for branded products and gift packaging

Cost-Focused or Simpler Wooden Boxes

MOQ: 1,000 pcs

Suitable for basic structures and finishes

Application Indurstry

Our custom wooden boxes are commonly used in the following industries.

How we wok

This is how we usually work with clients on custom wooden box projects.

We Ask Questions Early

We ask detailed questions at the beginning.

This helps avoid wrong assumptions and costly changes later.

We Don’t Push Risky Designs

If a design looks good but is risky for mass production,

we will tell you before sampling.

We Focus on What Can Be Reproduced

Samples are not the goal.

Stable and repeatable mass production is.

We Keep Things Clear, Not Complicated

Structure, materials, finishes, logo methods, and lead time are confirmed step by step.

Nothing important is left unclear.

We Respect Boundaries

If something is not suitable for your timeline, quantity, or budget,

we will tell you directly instead of saying yes first.

We Work for Long-Term Cooperation

Most of our projects come from repeat clients.

We value consistency and reliability more than one-time orders.

Common Questions We Get

If you have questions not listed here, feel free to contact us. We prefer to clarify things early rather than fix problems later.

Can you make custom boxes if I don’t have a design file?

Yes.

You can share references, sketches, or just tell us what you want to pack.

We can help you define the structure and details step by step.

What is your minimum order quantity?

For most mid to high-end custom wooden boxes, the MOQ is 300 pcs.

For simpler or cost-focused designs, the MOQ is usually 1.000 pezzi.

How long does sampling take?

Sampling usually takes 10–15 days, depending on structure and finish.

More complex designs may take slightly longer.

How long is mass production?

Mass production usually takes 35–50 days after sample approval.

The exact time depends on quantity and box complexity.

Can I make changes after seeing the sample?

Yes, small adjustments are possible at the sampling stage.

Major design changes may affect cost and lead time.

Do you help choose materials and structure?

Yes.

We don’t just follow instructions — we also point out risks and suggest safer options for mass production.

Can you match the sample exactly in mass production?

We aim to keep mass production consistent with the approved sample.

Minor differences may still occur due to materials and finishing, but we control them within acceptable ranges.