Perfume brands often lose products after shipping, even with premium boxes.

The real problem is not the box. It is hidden inside the foam.

Foam molds need custom density because different perfume bottle shapes create different forces during movement, vibration, and storage.

If density does not match the bottle, damage will happen slowly or suddenly.

I want to explain this from my real production experience, not theory.

I have seen too many failures caused by “good-looking” foam.

Before we go deeper, I want you to remember one thing.

Foam is not decoration. Foam is a mechanical system.

Why does bottle weight and center of gravity determine foam density needs?

Many packaging problems start with a simple mistake.

People look at bottle size, but they ignore weight and balance.

Bottle weight and center of gravity decide how force moves through the foam during transport.

If density does not match these forces, the bottle will shift or stress will build.

Understanding center of gravity in perfume bottles

Every bottle has a center of gravity.

This point decides how the bottle reacts when the box is shaken or dropped.

From my experience, perfume bottles usually fall into three groups:

| Type de bouteille | Répartition du poids | Common Risk |

|---|---|---|

| Tall bottle with metal cap | Top-heavy | Neck stress and cap loosening |

| Bouteille en verre épais | Bottom-heavy | Base cracks and vertical shock |

| Sculptural bottle | Irrégulier | Rotation and side pressure |

When foam density is chosen without this analysis, problems appear.

Why heavier bottles need higher base density

A heavy bottle pushes down on foam all the time.

This pressure is constant, even when the box is not moving.

If foam density is too low:

- The foam compresses early

- The bottle sinks

- The neck becomes a pivot point

Over time, vibration creates rotation.

Rotation creates torque.

Torque damages seals and glass.

For heavy bottles, I always specify firmer foam at the base.

This is not about hardness.

This is about load-bearing ability.

Why top-heavy bottles need balanced density, not just harder foam

Many people think top-heavy bottles need harder foam everywhere.

This is wrong.

Hard foam transfers shock.

It does not absorb it.

Top-heavy bottles need:

- Stable support at the base

- Elastic absorption near the neck

- Controlled compression, not zero movement

In my drop tests, uniform high-density foam caused more failures than mixed density foam.

My real-world mistake that taught me this lesson

Early in my career, I used one foam density for an entire perfume line.

The bottles were different heights but similar volumes.

Everything looked perfect in the factory.

After shipping, leakage reports started.

The cause was simple.

Tall bottles had higher centers of gravity.

The foam was not designed for that.

Since then, weight and center of gravity are always my first questions.

How do different bottle shapes distribute stress differently during transport?

Shape matters more than people think.

Two bottles with the same weight can behave very differently.

Bottle shape decides where stress concentrates inside the foam.

If foam density does not respond to this, cracks will appear at weak points.

Stress is not evenly distributed

During transport, boxes experience:

- Vertical drops

- Horizontal vibration

- Rotational movement

Stress always travels to contact points.

Different shapes create different contact patterns:

| Bottle Shape | Stress Concentration Area |

|---|---|

| Cylindrical | Even side pressure |

| Square | Coins et bords |

| Flat oval | Lateral compression |

| Sculptural | Random high-stress points |

Foam must respond to these patterns.

Why angular bottles need controlled compression

Angular bottles look strong.

In reality, their corners are fragile.

Hard foam presses directly on edges.

Soft foam allows movement into edges.

Both are dangerous.

For angular bottles, I prefer:

- Medium density foam

- Larger contact surface

- Rounded cavity edges

This spreads stress instead of focusing it.

Why curved bottles tolerate softer foam better

Curved surfaces distribute pressure naturally.

They work well with elastic foam.

But this does not mean very soft foam is safe.

Soft foam still allows movement.

Movement creates rotation.

Rotation damages necks and caps.

So even for curved bottles, density must match weight.

Asymmetrical designs need custom zoning

Modern perfume design loves asymmetry.

From a packaging view, this is the hardest category.

Asymmetrical bottles:

- Rotate easily

- Tilt under vibration

- Create uneven foam compression

For these bottles, I often design foam with zones.

Example zoning approach:

| Foam Zone | Fonction |

|---|---|

| Lower zone | Load support |

| Mid zone | Lateral control |

| Upper zone | Vibration absorption |

One-density foam cannot do this job.

Why can foam that is too soft be as dangerous as foam that is too hard?

This question surprises many buyers.

Soft foam feels safe when you touch it.

Foam that is too soft creates invisible movement that causes long-term damage.

The danger of micro-movement

Soft foam compresses easily.

At first, this feels protective.

But during transport:

- Vibration repeats thousands of times

- Foam slowly loses shape

- The bottle starts to move

This movement is small.

But it is constant.

Over time, this causes:

- Cap loosening

- Seal fatigue

- Neck stress

Most leakage problems start this way.

Why adding more soft foam does not help

Many brands respond to damage by adding more foam.

This often makes things worse.

More soft foam means:

- More compression

- More rebound

- More movement

The bottle becomes suspended, not supported.

I have opened many returned boxes where the bottle was floating inside foam.

The danger of foam that is too hard

Hard foam feels strong.

It holds the bottle firmly.

But hard foam:

- Transfers shock

- Creates stress points

- Does not absorb energy

In drop tests, I have seen:

- Cracks at neck contact points

- Base fractures

- Edge chips

The outer box was perfect.

The bottle was not.

The balance between restraint and absorption

Good foam density does two things:

- Limits movement

- Absorbs energy

If it only does one, it fails.

This balance is why custom density matters.

How does custom foam density protect fragile areas like the neck and base?

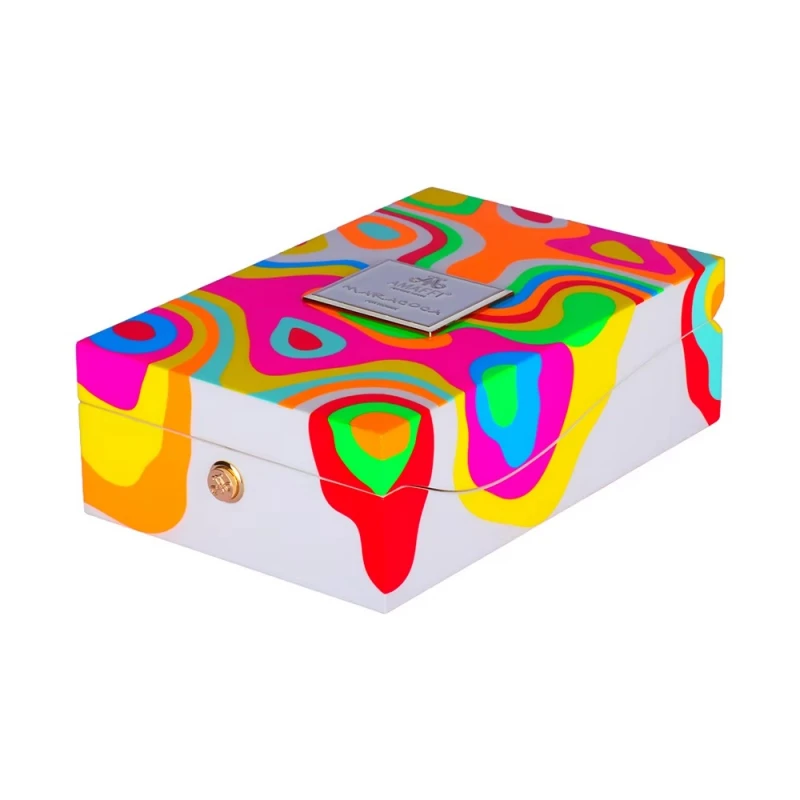

%[Boîte blanche de luxe avec logo Destetico

Not all parts of a perfume bottle are equal.

Some areas fail first.

Custom foam density protects fragile areas by managing force direction and timing.

The neck is the most sensitive area

The neck connects:

- Verre

- Pump

- Cap

This area suffers from:

- Rotation

- Torsion

- Repeated vibration

If foam is too loose near the neck:

- The bottle twists

- The seal weakens

If foam is too hard:

- Stress transfers directly to glass

I always reduce density slightly around the neck.

This allows controlled absorption.

The base carries most of the load

The base supports:

- Bottle weight

- Vertical shock

For heavy bottles, base foam must:

- Resist compression

- Maintain shape over time

If base foam collapses:

- The bottle tilts

- Stress shifts to the neck

This is why I often use higher density foam at the base.

Gradient density is often the best solution

For many perfume bottles, I use gradient density.

Example structure:

| Zone | Density Purpose |

|---|---|

| Base | Load bearing |

| Milieu | Stabilité |

| Cou | Vibration absorption |

This structure works as a system.

Foam must work with the wooden box

Foam does not work alone.

It works with the wood structure.

If the wooden box flexes:

- Foam must compensate

If the box is rigid:

- Foam must absorb more shock

At WooDo, we always test foam and wood together.

Why is density matching critical for long-term storage, not just shipping?

Many people focus only on shipping.

This is a mistake.

Long-term storage exposes foam density problems slowly but permanently.

Foam fatigue is real

Foam changes over time.

Under constant pressure:

- Cells collapse

- Elasticity reduces

- Shape is lost

If density is too low, this happens faster.

Once foam collapses:

- The bottle loses support

- Protection is gone

Why collectors and export buyers face higher risk

Luxury perfumes are often:

- Stored for years

- Kept in warehouses

- Displayed in boxes

Foam must hold shape long-term.

I have seen:

- Bottles leaning after one year

- Caps under constant stress

- Boxes that look fine outside

The damage was inside.

Proper density extends packaging life

Correct density:

- Resists permanent compression

- Maintains contact points

- Keeps force balanced

This is critical for:

- Éditions limitées

- High-value perfumes

- International distribution

My long-term testing approach

In my practice, we test foam by:

- Simulating storage load

- Leaving bottles compressed

- Rechecking after months

If foam does not recover, we reject it.

This saves brands from future complaints.

Conclusion

Custom foam density is not optional.

It is essential for protecting perfume bottles over time and movement.

Nom de marque : WoodoBox

Slogan : Boîtes en bois sur mesure, fabriquées à la perfection