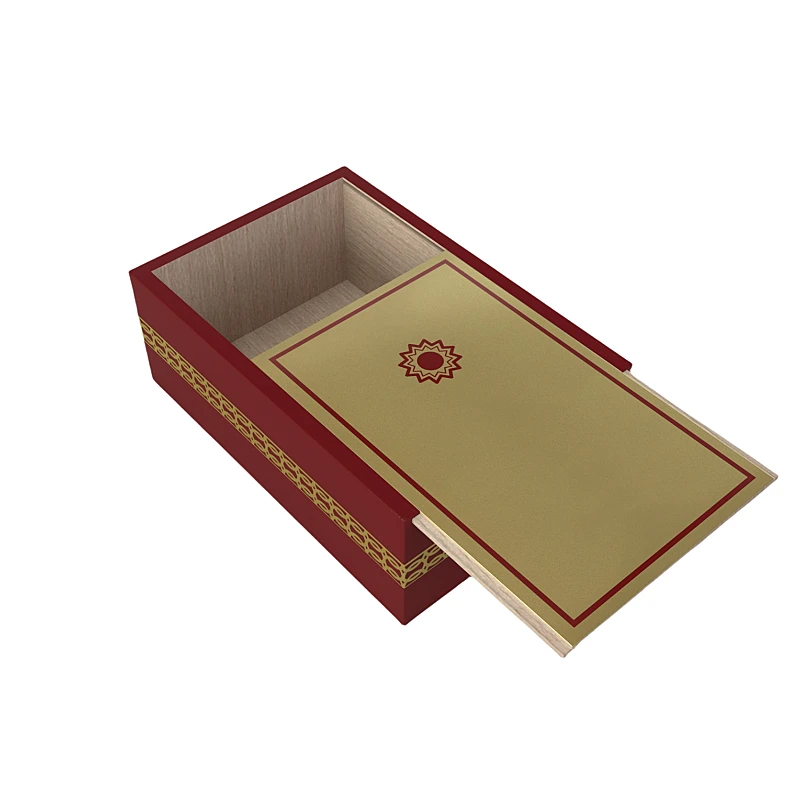

Sliding lid wooden boxes look clean, smart, and efficient. Many buyers choose them fast. But behind this simple look, real design limits can quietly hurt cost, use, and customer feel if not handled early.

A sliding lid wooden box is compact and simple, but it comes with strict tolerance, usability, and finish limits that buyers must understand before choosing it for a real product.

I have worked with many clients who loved this structure at first sight. Some succeeded. Others learned hard lessons later. This article breaks down what really works, what does not, and how I decide if this box is right.

Why Sliding Lid Boxes Are Chosen for Compact and Minimal Designs

Sliding lid boxes attract buyers because they look quiet and controlled. There is no noise in the design. No metal. No extra parts. For compact items, this feels like a smart choice.

Small boxes feel cluttered fast. Sliding lids reduce visual weight and keep the structure tight, which is why many minimal brands prefer them.

The visual logic behind sliding lids

I often explain this in very direct terms. A sliding lid box is almost a rectangle with a line. That line is the lid. Nothing else interrupts the surface.

This helps in three ways:

- The box looks smaller than it really is

- The edges feel clean in photos

- Branding stands out more clearly

For brands that care about calm visuals, this matters.

Space efficiency in real shipping and storage

Sliding lids remove hinge height. They also remove lid overlap. This saves space.

From my experience, this matters most in two cases:

- Products shipped in bulk cartons

- Products sold in sets or kits

Below is a simple comparison I often show buyers:

| Type de boîte | Extra Height | Matériel | Shipping Efficiency |

|---|---|---|---|

| Sliding Lid | Aucun | Non | Haut |

| Hinged Lid | Moyen | Oui | Moyen |

| Top & Bottom | Haut | Non | Faible |

This is not theory. I see it on pallets.

Where buyers emotionally connect with this structure

Many buyers feel sliding lids are “honest.” The box opens without ceremony. That fits brands that want a natural or functional tone.

But emotion alone should not decide structure. I always push clients to slow down and test the box with their actual product.

My early warning to first-time buyers

I always say this clearly:

A sliding lid box looks simple, but it behaves strictly.

If you want flexibility later, this may not be the safest choice. Simplicity removes margin for error.

Product Types That Truly Match a Sliding Lid Structure

Not every product belongs in a sliding lid box. Some fit naturally. Others fight the structure from day one.

Sliding lid boxes work best when the product is light, stable, and rarely opened after purchase.

Products that work well

I have seen strong results with these product types:

- USB sets

- Tea collections

- Light gift items

- Flat accessories

- Promotional kits

These products share three traits. They are light. They do not shift. They do not need daily access.

Products that struggle

I advise caution for:

- Heavy glass bottles

- Multi-layer foam inserts

- Products opened daily

- Luxury items with ritual value

Sliding lids do not lock. They also slide fully out. This changes how safe and premium the box feels.

Insert stability is the hidden key

The insert does more work in a sliding lid box than buyers expect.

Why inserts matter more here

There is no hinge stop. There is no lid weight to press down. So the insert must:

- Hold the product firmly

- Prevent movement when sliding

- Stay flat after humidity change

If the insert fails, the whole box feels cheap.

Common insert mistakes

I see these errors often:

| Erreur | Résultat |

|---|---|

| Loose insert | Product shifts |

| Soft foam | Lid catches |

| High insert | Lid scratches |

My rule of thumb

If the product can survive being slid in and out 50 times without movement, then the structure is acceptable.

If not, I usually suggest another box style.

Cost Expectations: Where Sliding Lids Save Money—and Where They Don’t

Many buyers assume sliding lid boxes are cheaper. This is only half true.

Sliding lid boxes save money on hardware and assembly, but they often cost more in machining, sanding, and testing.

Where costs are reduced

The savings usually come from:

- No hinges

- No magnets

- Fewer assembly steps

This reduces labor time per unit. In large orders, this helps.

Where costs increase

Here is the part buyers often miss.

CNC groove precision

The groove must be exact. Too tight, the lid sticks. Too loose, it rattles.

This requires:

- Slower CNC speed

- Better tooling

- More frequent checks

Extra sanding work

After machining, every groove edge must be smooth.

This adds manual labor.

The finish factor

Paint, oil, and veneer all add thickness.

Even 0.2 mm can break the slide.

I always push for real finish testing before mass production.

Cost comparison at different volumes

| Quantité | Sliding Lid | Hinged Lid |

|---|---|---|

| 300 pcs | Souvent plus élevé | Plus bas |

| 1000 pcs | Similar | Similar |

| 5000 pcs | Plus bas | Plus élevé |

Small orders feel the pain more.

My honest cost advice

If your order is under 500 pcs, do not assume sliding lids are cheaper. Ask for a full process breakdown.

Hidden Design Constraints Buyers Often Discover Too Late

This is where problems usually appear. Not in drawings. Not in photos. But after production.

Sliding lid boxes fail when tolerance, finish, and user behavior are not tested together.

Tolerance sensitivity explained simply

The lid and groove must balance friction.

That balance changes after:

- Painting

- Oiling

- Humidity change

What slides well in raw wood may fail later.

Scratch risk is real

Sliding motion creates contact.

If the surface is soft, scratches appear fast.

Common risky finishes:

- Peinture mate

- Dark stains

- Soft oil

User experience is often ignored

I always ask one question:

Can a customer open this box easily with one hand?

Most sliding lids cannot.

This matters for:

- Retail counters

- Gift moments

- Premium positioning

No natural stop problem

The lid slides fully out. There is no pause point.

This creates risks:

- Lid drops

- Lid gets lost

- Customer feels awkward

Late-stage complaints I hear

| Plainte | Root Cause |

|---|---|

| Lid sticks | Finish thickness |

| Feels cheap | No opening ritual |

| Scratches | Surface friction |

These are hard to fix after mass production.

A Clear Decision Guide: Is a Sliding Lid Box Right for Your Product?

I do not reject sliding lid boxes. I just use them carefully.

A sliding lid box is right only when product weight, usage frequency, and brand tone align with its limits.

My personal decision checklist

I walk clients through these points:

Product factors

- Weight under 1 kg

- Stable shape

- Low access frequency

Brand factors

- Minimal tone

- Functional message

- Low ceremony need

Production factors

- Tested finish samples

- Stable insert design

- Controlled tolerance

Simple yes or no table

| Question | Oui | Non |

|---|---|---|

| Product is light | ✔ | ✖ |

| Box opened often | ✖ | ✔ |

| Premium ritual needed | ✖ | ✔ |

If you see more ✖ than ✔, stop.

My final practical advice

Choose this structure with intent, not trend.

Sliding lid boxes reward discipline. They punish assumption.

If used correctly, they feel clean and honest. If used blindly, they create silent frustration.

Conclusion

Sliding lid wooden boxes are compact and clean, but strict. When product, finish, and use align, they work beautifully. When they don’t, problems appear fast.

WoodoBox – Premium Wooden Packaging Manufacturer in China

Boîtes en bois sur mesure, fabriquées à la perfection