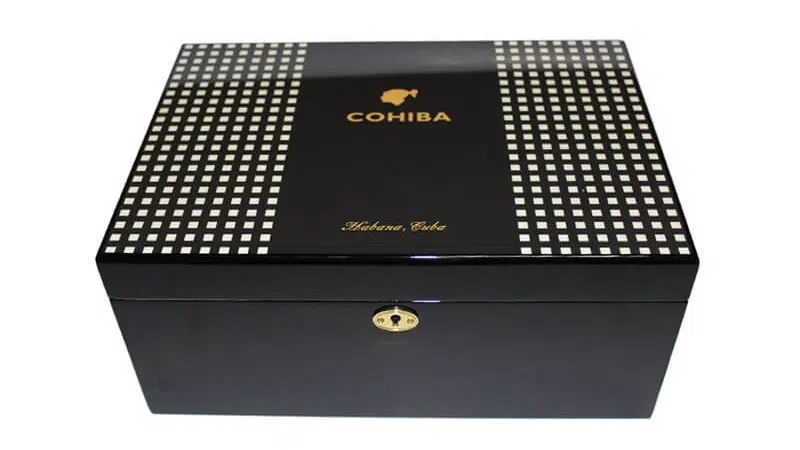

La laca de piano no es sólo estética, también protege. Para las cajas de puros de primera calidad, un acabado duradero y resistente a los arañazos es esencial para su valor y presentación a largo plazo.

Pero, ¿qué confiere a la laca para pianos su resistencia y cómo podemos mejorar aún más esa protección?

Tras años fabricando cajas de puros de alto brillo para coleccionistas y marcas de lujo, he perfeccionado las técnicas que convierten la laca de un acabado delicado en un escudo resistente.

¿Qué propiedades de la laca para pianos contribuyen a su dureza y durabilidad naturales?

La laca para pianos -a menudo basada en sistemas de poliéster o poliuretano- es dura y densa por naturaleza. Una vez curada, forma una película sólida que resiste la abrasión, la humedad y los pequeños impactos.

En comparación con la nitrocelulosa tradicional, la moderna laca para piano1 ofrecen una mayor densidad de reticulación, lo que hace que el acabado sea más duro y más resistente a los productos químicos.

Propiedades clave que mejoran la durabilidad

- Alto contenido en sólidos: Crea una gruesa capa protectora

- Estructura polimérica reticulada: Crea una superficie más dura tras el curado

- Resistencia a los rayos UV2: Ayuda a reducir la degradación con el paso del tiempo

- Conservación del brillo: Mantiene el acabado impecable con un mantenimiento mínimo

Nuestros clientes nos dicen a menudo que eligieron el lacado para pianos porque querían una caja que se mantuviera como nueva, incluso después de años de uso. Eso solo funciona con el sistema de lacado adecuado.

¿Cómo afecta la técnica de estratificación a la resistencia de la superficie al desgaste diario y los arañazos?

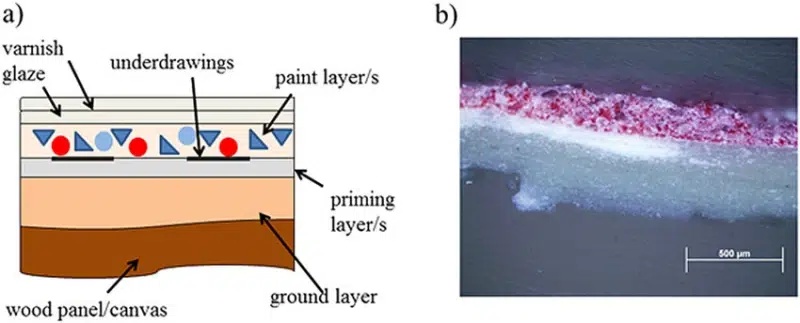

El número de capas -y la forma de aplicar cada una- influye directamente en la resistencia del acabado a arañazos y rozaduras.

Cada capa transparente añade una microbarrera de protección. Cuando se superpone correctamente, la laca forma una superficie multicapa3 que distribuye la tensión superficial, reduciendo la posibilidad de arañazos profundos.

Prácticas recomendadas para la estratificación resistente a arañazos

- Aplicar 5-8 capas finas y uniformes en lugar de menos gruesas

- Lijar ligeramente entre capas con grano 800-1500 para mejorar la adherencia

- Utilizar todo el tiempo de apagado del flash antes de volver a aplicar para evitar la aparición de zonas blandas

- Acabado con una capa fluida (capa fina final para suavizar la tensión superficial)

| Recuento de capas | Resistencia a los arañazos | Profundidad de brillo |

|---|---|---|

| 3-4 | Moderado | Básico |

| 5-6 | Alta | Rich |

| 7-8 | Excelente | Máximo |

Hemos descubierto que una capa demasiado gruesa puede provocar fragilidad, por lo que aumentamos la protección de forma lenta y constante.

¿Qué aditivos o formulaciones pueden mejorar la resistencia a los arañazos sin apagar el brillo?

No todas las lacas para piano son iguales. La formulación -especialmente el tipo de endurecedores y plastificantes utilizados- tiene un gran impacto en la resistencia al rayado.

Aditivos que ayudan

- Micropartículas de sílice4: Mejora la resistencia a la abrasión manteniendo la claridad

- Inhibidores UV5: Previene el reblandecimiento de la superficie por la exposición al sol

- Polímeros autorregenerativos6: Se encuentra en las fórmulas de PU más recientes; minimiza las marcas superficiales ligeras.

- Resinas de alto brillo con dureza incorporada: Reduce la necesidad de capas de acabado

Consejos de formulación

✔ Utilizar lacas con dureza Shore D superior a 70 para una fuerte protección de la superficie.

✔ Evitar plastificantes que reduzcan el brillo para obtener flexibilidad, a menos que sea específicamente necesario.

✔ Seleccione un sistema diseñado para "uso de sobremesa" o superficies muy sensibles al tacto.

Trabajamos con los proveedores para ajustar las fórmulas de lacado en función del uso final. Las cajas de puros reciben una fórmula distinta que, por ejemplo, los expositores de joyas.

¿Cómo puede curado adecuado7 influyen en la resistencia protectora a largo plazo de la laca?

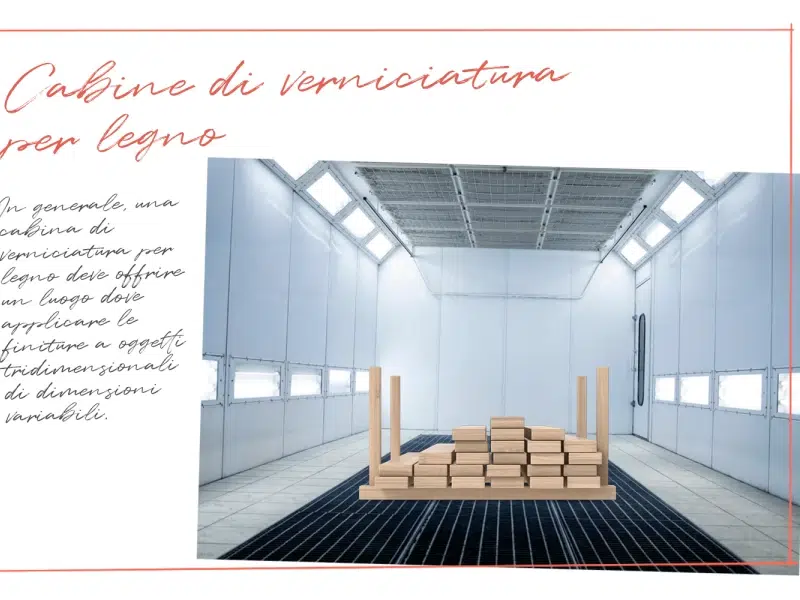

La resistencia de una superficie lacada no depende sólo de lo que se aplica, sino de cómo se endurece. Un curado adecuado permite que los enlaces químicos se formen completamente, haciendo que el acabado sea duro y duradero.

Factores clave del curado

- Tiempo: La dureza final puede tardar entre 5 y 7 días, aunque la superficie se note seca en 24 horas.

- Temperatura20-25°C ambiente es ideal para una reticulación completa

- Control de la humedad: Previene el rubor y los puntos blandos

- Curado al horno (opcional): Acelera el endurecimiento de los sistemas de PU o poliéster

| Tipo de laca | Secado inicial | Tiempo de curado completo |

|---|---|---|

| Nitrocelulosa | 1-2 horas | 2-3 días |

| Poliuretano | 6-8 horas | 5-7 días |

| Poliéster | 24 horas | 5-7 días |

✔ No empaquete ni pula nunca las cajas de puros lacadas antes del curado completo.

✔ Seguimiento de las fechas de los lotes para garantizar la coherencia de la durabilidad.

Al principio de mi carrera, envié un lote demasiado pronto y recibí quejas sobre "esquinas blandas". Desde entonces, cada caja descansa una semana entera antes de salir de la línea.

¿Qué tratamientos o revestimientos posteriores al acabado ayudan a reforzar la superficie lacada?

Una vez finalizado el pulido, algunos tratamientos opcionales pueden añadir resistencia adicional a los arañazos sin reducir la claridad visual del acabado.

Mejoras posteriores al acabado

- Cera microcristalina8: Añade una capa protectora que repele el polvo y las huellas dactilares.

- Pulimentos protectores sin silicona9: Ayuda a reducir la estática y mejora el planeo

- Revestimientos nanocerámicos10: Crea una superficie hidrófoba y antiarañazos (utilizada en el detallado de automóviles de lujo).

✔ Aplicar a mano con una almohadilla de microfibra

✔ Evitar aceites o compuestos que ablanden la laca o amarilleen con el tiempo.

✔ Reaplicar ceras o pulimentos cada 6-12 meses para piezas de exposición a largo plazo.

Para los coleccionistas, a menudo incluimos una lata de muestra de nuestra cera preferida. Aporta un tacto suave como la mantequilla y protege contra los anillos o los arañazos de las uñas.

¿Cómo pueden los usuarios finales cuidar las superficies lacadas de los pianos para conservar su aspecto impecable?

Incluso la mejor laca puede mostrar desgaste si se manipula con descuido. Para un uso prolongado, es fundamental que el usuario final sepa cómo limpiar y almacenar el producto correctamente.

Consejos para el cuidado del usuario

- Polvo sólo con paños de microfibra11-sin toallas de papel

- Evite los productos de limpieza a base de alcohol o amoniaco

- Mantener alejado de la luz solar directa y de habitaciones muy húmedas

- Conservar a temperatura ambiente para evitar el estrés por expansión

- Utilizar guantes suaves para la manipulación durante la exposición

✔ Añade una tarjeta de cuidados con cada producto de alto brillo

✔ Se recomienda un pulido anual con cera o esmalte no abrasivo12

Diseñamos nuestros embalajes para proteger durante el envío, pero también para tener en cuenta los hábitos del usuario. Por eso nuestras bandejas interiores sujetan la caja con un contacto mínimo con la superficie.

Conclusión

El lacado para piano aporta un brillo inigualable, pero el verdadero lujo también implica un rendimiento duradero. Cuando se hace bien, es tan resistente como bello.

Para mejorar la resistencia al rayado:

- Utilice el sistema de lacado y la formulación adecuados

- Aplicar capas finas con lijado y curado adecuados

- Acabado con tratamientos posteriores que conservan el brillo y la claridad

- Educar a los clientes sobre el cuidado y la manipulación diarios

El lujo no es sólo lo que se ve, sino lo que se mantiene a lo largo del tiempo. Y la laca de piano, aplicada correctamente, lo consigue.

Marca: WoodoBox

Eslogan: Cajas de madera personalizadas, hechas a la perfección

Página web: www.woodobox.com

-

Explore las ventajas del lacado para pianos, incluidas su durabilidad y su atractivo estético, para comprender por qué es la opción preferida para acabados de alta calidad. ↩

-

Descubra la importancia de la resistencia a los rayos UV en los revestimientos para garantizar la longevidad y mantener el aspecto, especialmente en los acabados para pianos. ↩

-

Descubra cómo una superficie multicapa puede mejorar significativamente la resistencia a los arañazos, garantizando que sus proyectos resistan el paso del tiempo. Consulte este enlace informativo. ↩

-

Descubra cómo las micropartículas de sílice mejoran la resistencia al rayado y la claridad de los revestimientos, garantizando un acabado duradero. ↩

-

Conozca el papel de los inhibidores de UV en la prevención de los daños superficiales causados por la luz solar, cruciales para mantener la longevidad del producto. ↩

-

Descubra la innovadora tecnología que hay detrás de los polímeros autorreparadores y cómo minimizan las marcas superficiales para conseguir un acabado impecable. ↩

-

Comprender el curado adecuado puede mejorar sus conocimientos sobre los acabados lacados y su durabilidad, garantizando mejores resultados en sus proyectos. ↩

-

Descubra las ventajas de la cera microcristalina para mejorar la protección de la superficie y la claridad de sus acabados lacados. ↩

-

Conozca las ventajas de los pulimentos protectores sin silicona para mantener la integridad y el aspecto de sus superficies lacadas. ↩

-

Descubra cómo los revestimientos de nanocerámica pueden proporcionar una protección y longevidad superiores a sus superficies lacadas. ↩

-

Descubra las ventajas de utilizar paños de microfibra para la limpieza, que garantizan que sus superficies permanezcan impecables y sin arañazos. ↩

-

Descubra cómo la cera o el esmalte no abrasivos pueden mejorar y proteger sus acabados lacados, manteniéndolos como nuevos. ↩