Las cajas de regalo de alto brillo requieren una precisión absoluta durante cada etapa de la aplicación de la laca. Pero incluso con una mano de obra perfecta, factores ambientales como la temperatura, la humedad y el polvo pueden determinar el resultado final.

Entonces, ¿cuáles son las condiciones ambientales ideales para obtener un embalaje impecable, sin defectos y con un acabado espejo?

Permítanme explicarlo basándome en mis años de experiencia dirigiendo un taller de acabados que produce cajas de madera de alto brillo para marcas de lujo de todo el mundo.

¿Cómo influyen la temperatura y niveles de humedad1 afectar curado de laca2 y calidad de la superficie3?

La temperatura y la humedad afectan directamente al flujo, al secado y al curado de la laca. Incluso pequeñas fluctuaciones pueden provocar enrojecimiento, burbujas, piel de naranja o grietas.

Si desea obtener un acabado liso y brillante, como el del vidrio, necesita tener un control total sobre el clima.

Rangos ideales para la aplicación de laca

| Factor medioambiental | Gama recomendada |

|---|---|

| Temperatura | 20-25°C (68-77°F) |

| Humedad relativa | 50-60% RH |

Problemas causados por las malas condiciones

- Demasiado frío (<18 °C): La laca se vuelve demasiado viscosa → patrón de pulverización irregular, curado lento.

- Demasiado calor (>28 °C): La laca se seca demasiado rápido → formación de costras en la superficie, atrapamiento de disolvente.

- Demasiado seco (<40% RH): Aumenta la electricidad estática → atrae el polvo.

- Demasiado húmedo (>65% HR): Provoca enrojecimiento (manchas blancas turbias) y superficies blandas.

En verano, utilizamos deshumidificadores industriales. En invierno, calentamos el espacio antes de pulverizar. Estos ajustes marcan la diferencia en la calidad del acabado.

¿Por qué es importante la circulación del aire en un taller de acabados de alto brillo?

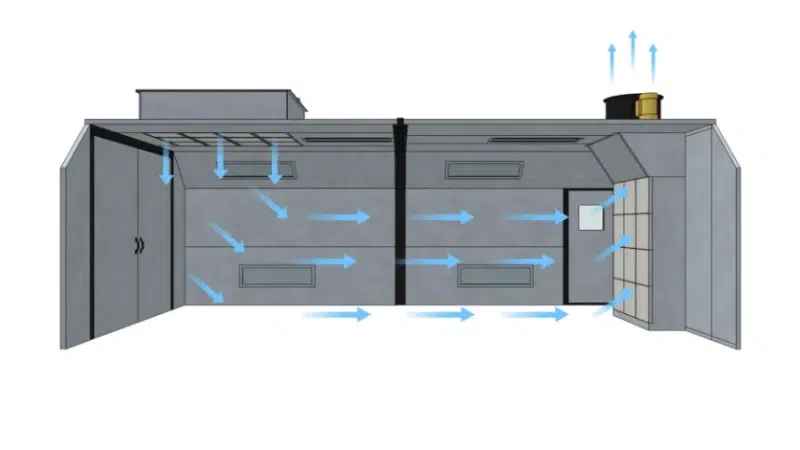

El flujo de aire ayuda a mantener un secado uniforme, evita la acumulación de exceso de pulverización y controla las partículas en suspensión. Pero tiene que ser controlado. Si se utiliza en exceso, se levanta polvo. Si se utiliza en cantidades insuficientes, se produce neblina o niebla de disolvente.

Requisitos clave del flujo de aire

✔ Flujo de aire laminar4: Flujo suave, horizontal o vertical, que aleja las partículas de la superficie.

✔ Sistema de presión positiva5: Evita que entre aire sucio en la cabina manteniendo una presión interna más alta.

✔ Ventiladores de extracción con filtros6: Elimina los disolventes y las gotas en suspensión en el aire al filtrar el aire saliente.

✔ Entrada de aire fresco con filtro HEPA: Garantiza que el aire entrante sea limpio, libre de partículas y climatizado.

¿Qué ocurre sin una circulación adecuada?

- Asentamiento del polvo: El estancamiento del aire permite que las partículas caigan sobre la laca húmeda.

- Secado desigual: Las superficies cercanas a las paredes o al suelo se secan de forma diferente a las que están al aire libre.

- Brillo inconsistente: La niebla de disolvente puede depositarse sobre el acabado, dejando una película opaca.

Hace dos años sustituimos nuestro sistema básico de extracción por una cabina de flujo cruzado descendente, lo que redujo los defectos en un 80%.

¿Qué papel desempeña el control del polvo en la prevención de imperfecciones superficiales?

Incluso la partícula de polvo más pequeña se convierte en un defecto visual bajo un acabado de alto brillo. Por eso control del polvo7 es una de las partes más importantes, y más ignoradas, de la producción de cajas de alta gama.

De dónde viene el polvo

- Fibras en suspensión: Ropa, trapos, embalajes de cartón.

- Tráfico peatonalLos zapatos traen suciedad del exterior.

- Áreas de lijado y corte: El polvo fino de madera puede permanecer durante días.

- Sistemas de climatizaciónLos conductos de aire sin filtrar distribuyen partículas finas.

Medidas de control del polvo

✔ Alfombrillas adhesivas: Quita la suciedad de los zapatos antes de entrar.

✔ Ropa antiestática para salas blancas: Reduce la pérdida de fibra y la atracción del polvo.

✔ Zonas separadas para lijado y acabado: Nunca lije donde haya pulverizado.

✔ Filtración de aire HEPA8: Filtra el 99,971 % de las partículas ≥0,3 micras.

✔ Limpieza diaria en húmedo: Fregonas, no escobas: nada de barrer en seco.

En nuestra sala de acabado no entra cartón, papel ni tela. Incluso las bandejas de las cajas son de plástico o metal para evitar la pérdida de fibras.

¿Cómo pueden afectar las condiciones de iluminación a la inspección visual durante la producción?

La iluminación no solo nos ayuda a ver los defectos, sino que influye en cómo percibimos el color, el brillo y la textura de la superficie. Una iluminación adecuada es una parte fundamental del control de calidad en los acabados de lujo.

Configuración ideal de iluminación

- D65 Luz diurna (6500 K)9: Luz blanca neutra para una combinación precisa de colores.

- Múltiples ángulos de iluminación: La luz cenital + lateral revela defectos de profundidad y superficie.

- CRI > 90 (Índice de reproducción cromática10): Fuente de luz de alta fidelidad que revela el color real y los defectos.

- Comprobaciones destacadas: El haz enfocado revela marcas de remolino, polvo y ondulaciones en la superficie.

Errores comunes en la iluminación de talleres

- Basándose en tubos fluorescentes amarillos11—color inexacto y visibilidad deficiente del brillo.

- No comprobar el acabado debajo de Condiciones de iluminación en tiendas minoristas (por ejemplo, LED cálidos, halógenos).

- Usando luz irregular—Las sombras ocultan la textura de la superficie. como piel de naranja o neblina.

Realizamos las inspecciones finales en una cabina con iluminación intercambiable: luz diurna D65, luz de tienda TL84 e incandescente cálida. Si se ve bien bajo las tres, sabemos que es impecable.

¿Qué equipos o configuraciones ayudan a mantener un entorno de producción estable y limpio?

Mantener las condiciones ideales no es cuestión de conjeturas. Requiere equipos que supervisen, controlen y filtren su entorno las 24 horas del día, los 7 días de la semana.

Equipo esencial para talleres

✔ Cabina de pulverización con presión positiva12

Mantiene el polvo fuera y el flujo de aire constante durante la aplicación.

✔ Climatización con deshumidificadores y calefactores

Mantiene una temperatura de entre 20 y 25 °C y una humedad de entre 50 y 60 % durante todo el año.

✔ Sistema de filtro HEPA13

Filtración multietapa tanto del aire de admisión como del aire de escape.

✔ Suelos y bancos de trabajo antiestáticos

Reduce la atracción del polvo en superficies lacadas.

✔ Termohigrómetros14

Controla la temperatura y la humedad en tiempo real. Está instalado en todas las paredes de nuestra cabina.

✔ Diseño del taller por zonas

- Lijado → Sala aislada

- Acabado por pulverización → Cabina controlada

- Pulido y abrillantado → Área de mesa estilo sala limpia

Desde que actualizamos a una cabina con filtro de tiro descendente y control de humedad, hemos pasado seis meses seguidos sin que ningún cliente haya devuelto un producto por defectos en la superficie.

¿Cómo afectan los cambios climáticos estacionales a la consistencia en acabados de alto brillo15?

Los cambios estacionales en la temperatura y la humedad pueden arruinar la consistencia entre lotes. Lo que parece impecable en invierno puede agrietarse o empañarse en verano, a menos que se tenga en cuenta el clima.

Problemas estacionales

- Verano: Alta humedad → lacado sonrojado16, ablandamiento de la superficie, tiempos de curado prolongados.

- Invierno: Aire frío → la laca se espesa, provoca piel de naranja o patrones de pulverización irregulares.

- Primavera/Otoño: Condiciones variables → secado impredecible, inconsistencia en el brillo.

Cómo lo gestionamos

✔ Talleres sobre zonas climáticas: Aire acondicionado y deshumidificadores independientes en cada área de trabajo.

✔ Ajustes por lotes: Las proporciones del diluyente y la presión de pulverización se ajustan en función de la temperatura del aire y la viscosidad de la laca.

✔ Adaptación del tiempo de curadoLas cabinas de secado permanecen activas durante más tiempo en los meses más fríos.

✔ Registros medioambientales: Cada ciclo de producción se registra con la temperatura, la humedad y las notas del lote para garantizar la trazabilidad.

Nuestros clientes suelen volver a realizar pedidos meses después. Gracias a los registros climáticos y al control de procesos, podemos igualar los acabados incluso con un año de diferencia.

Conclusión

La producción de cajas de regalo impecables y muy brillantes no solo depende del barniz, sino también de todo lo que hay en el aire a su alrededor.

Para eliminar defectos y ofrecer consistencia a un nivel de lujo:

- Controle la temperatura y la humedad dentro de márgenes estrictos.

- Aísle las fuentes de polvo y mantenga un espacio de trabajo limpio y filtrado.

- Utilice iluminación profesional para inspeccionar cada superficie desde todos los ángulos.

- Ajuste los parámetros del equipo y de pulverización según cambien las estaciones.

En los acabados de alta gama, el entorno es tu segundo artesano, y nunca se toma un día libre.

-

La humedad desempeña un papel importante en la aplicación de lacas. Aprenda a controlarla para obtener resultados óptimos en sus proyectos. ↩

-

Comprender el curado de la laca es esencial para lograr el mejor acabado. Explore este enlace para obtener más información sobre el proceso y los factores que lo influyen. ↩

-

La calidad de la superficie es fundamental para la estética y la durabilidad. Descubra cómo mejorarla mediante técnicas y condiciones adecuadas. ↩

-

Comprender el flujo de aire laminar puede mejorar sus técnicas de acabado y la calidad del producto. ↩

-

Descubra cómo un sistema de presión positiva puede mantener limpio su espacio de trabajo y mejorar la calidad del aire. ↩

-

Descubra cómo los extractores con filtros pueden mejorar la seguridad y la eficiencia en el entorno de su taller. ↩

-

Comprender el control del polvo puede mejorar significativamente la calidad del producto y reducir los defectos en los procesos de producción de alta gama. ↩

-

Los filtros HEPA son fundamentales para mantener un espacio de trabajo limpio, garantizar acabados de alta calidad y reducir las imperfecciones. ↩

-

Explorar D65 Daylight le ayudará a comprender su importancia para lograr una coincidencia precisa de colores y garantizar la calidad en la producción. ↩

-

Comprender el índice de reproducción cromática puede mejorar sus conocimientos sobre cómo la iluminación afecta a la percepción del color y al control de calidad. ↩

-

Conocer las desventajas de los tubos fluorescentes amarillos puede ayudarle a evitar errores comunes en la configuración de la iluminación y mejorar así la calidad de las inspecciones. ↩

-

Descubra cómo una cabina de pulverización con presión positiva puede mejorar su entorno de producción al mantener el polvo fuera y garantizar un flujo de aire constante. ↩

-

Descubra la importancia de los sistemas de filtros HEPA para mantener el aire limpio y reducir los contaminantes en su espacio de trabajo. ↩

-

Descubra cómo los termohigrómetros pueden ayudarle a mantener unos niveles óptimos de temperatura y humedad para mejorar la calidad de la producción. ↩

-

Descubra los consejos de los expertos sobre cómo mantener acabados de alto brillo para garantizar la calidad y la uniformidad durante todo el año. ↩

-

Aprenda sobre el enrojecimiento de la laca y los métodos de prevención para mejorar sus técnicas de acabado y evitar errores comunes. ↩