When producing luxury jewelry boxes, even small structural tweaks can lead to major cost savings—without compromising elegance or brand value.

Streamlining design elements like panel thickness, closures, or hardware can lower costs while maintaining the premium feel.

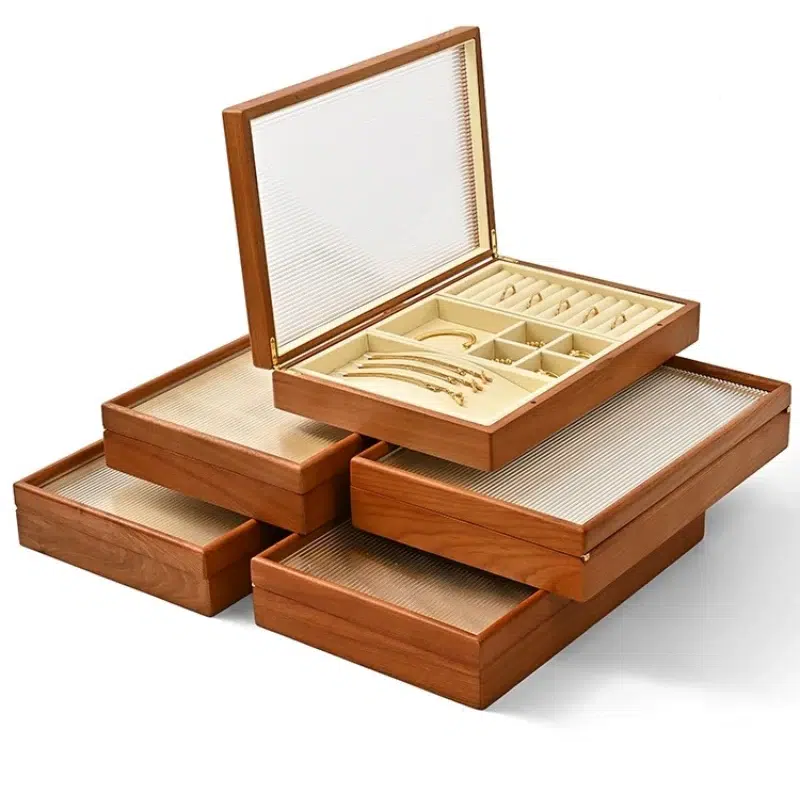

How can simplifying internal compartments lower material and labor costs?

Creating multiple compartments, ring holders, or layered trays adds complexity. Each element requires:

- More material (foam, lining, adhesives)

- Increased assembly time

- Precision fitting and alignment

By reducing the number of compartments or shifting to a universal insert layout, you cut both material waste and production time.

Simpler interiors don’t have to feel cheap—they just need smart layout planning and quality linings.

Why does reducing the thickness of wood panels make a big difference in pricing?

Thicker panels might feel sturdier, but they also:

- Use more material per unit

- Require stronger hinges or hardware

- Add to shipping weight and carton size

Switching from, say, 10mm to 6mm panels can reduce cost by 10–15%, depending on the wood type. Reinforcing thinner panels with inner frames or smart joinery keeps them structurally sound.

The key is maintaining strength while minimizing unnecessary bulk.

How can switching from metal to magnetic or ribbon closures cut production expenses?

Metal clasps, locks, and latches:

- Require precise installation

- Have a higher unit cost

- Are prone to defects if misaligned

Magnetic closures are:

- Easier to install (flush-set with adhesive)

- Sleek and modern

- Cost-effective at scale

Ribbon ties offer a romantic feel and are even more economical—especially for limited-use or gift-event boxes.

| Closure Type | Atractivo visual | Eficiencia de costes | Durabilidad |

|---|---|---|---|

| Metal Clasp | Clásico | Bajo | Alta |

| Magnet | Moderno | Alta | Medio |

| Ribbon Tie | Elegant | Muy alta | Bajo |

What impact does minimizing custom shapes or curves have on manufacturing efficiency?

Custom curves, scalloped edges, or asymmetrical lids may look unique, but:

- They require specialized molds or CNC programs

- Result in higher waste during cutting

- Are harder to wrap or veneer without bubbles or wrinkles

Sticking to straight lines, consistent angles, and standard profiles streamlines both fabrication and finishing.

This not only cuts machine time but also speeds up hand-assembly and quality checks.

How does using fewer hinges or hardware pieces reduce overall costs?

Every piece of hardware adds more than just its purchase cost:

- Additional steps in installation

- Higher rejection rate due to alignment issues

- Risk of rattling or squeaking over time

Switching from dual hinges to a single concealed hinge, or replacing metal support arms with soft-close tension magnets, reduces both parts and labor.

Fewer components = fewer failure points + faster assembly.

Why is standardizing box dimensions across product lines a smart cost-saving strategy?

Custom dimensions = custom tooling = custom problems.

When brands use the same exterior dimensions across collections, even if the interiors differ slightly:

- They can reuse CNC programs, jigs, and templates

- Buy materials and liners in bulk

- Reduce sampling time and errors

Plus, standardized boxes stack better in storage and shipping, reducing logistics costs.

Consistency in form can still allow creativity in finish, texture, and branding.

Marca: WoodoBox

Eslogan: Cajas de madera personalizadas, hechas a la perfección

Página web: www.woodobox.com