Wiederverwendbare Holzkisten müssen mehr als nur optisch ansprechend sein. Ohne strukturelle Festigkeit und strapazierfähige Materialien versagen sie schnell.

Um die Wiederverwendbarkeit zu gewährleisten, müssen Hersteller die Struktur verstärken, langlebiges Holz auswählen, robuste Beschläge verwenden, Schutzbeschichtungen auftragen und Umweltfreundlichkeit mit Langlebigkeit in Einklang bringen.

Entwürfe für den wiederholten Gebrauch erfordern ein Denken, das über den ersten Eindruck hinausgeht.

Welche strukturellen Verstärkungen sind erforderlich, um ein wiederholtes Öffnen und Schließen zu gewährleisten?

Jedes Öffnen belastet die Schachtel. Schwache Strukturen nutzen sich schnell ab.

Verstärkungen wie stabile Verbindungen, dickere Wände und geprüfte Deckelverhältnisse sorgen dafür, dass eine Box wiederholter Beanspruchung standhält.

Dünne Wände oder schwache Verbindungen mögen einmal halten, versagen jedoch nach 50 Öffnungen. Verstärkung bedeutet, mit bewährten Konstruktionsmethoden zu bauen, die sowohl die Ästhetik als auch die Funktion schützen.

Methoden zur strukturellen Verstärkung

- Verwenden Sie Finger- oder Schwalbenschwanzverbindungen für stabilere Kanten.

- Erhöhen Sie die Wandstärke für Deckel und Böden.

- Verwenden Sie Inneneckblöcke für zusätzliche Stabilität.

- Behalten Sie für ein ausgewogenes Verhältnis die Standardverhältnisse zwischen Deckel und Boden bei.

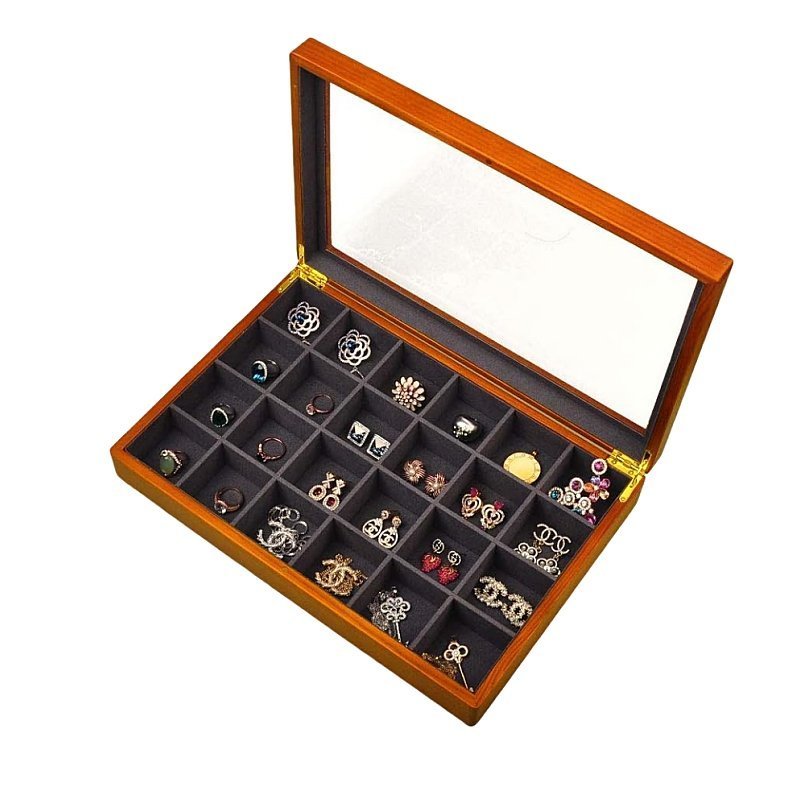

Ich habe einmal ein Projekt für eine Schmuckschatulle durchgeführt, bei dem der Kunde ursprünglich sehr dünne Seitenwände wünschte, um Kosten zu sparen. Nach dem Testen verformte sich der Deckel innerhalb weniger Wochen. Wir wechselten zu dickeren MDF-Platten mit Furnier und fügten verstärkte Verbindungen hinzu. Die Schatulle bestand dann wiederholte Belastungstests.

Wie wählt man die richtige Holzart für langfristige Haltbarkeit und Widerstandsfähigkeit aus?

Nicht alle Holzarten sind für den wiederholten Gebrauch geeignet. Einige sehen gut aus, sind aber nicht stabil genug.

In puncto Haltbarkeit sind Harthölzer oder Holzwerkstoffe mit hochwertigem Furnier besser geeignet als Weichhölzer oder instabile Alternativen.

Massive Harthölzer wie Mahagoni oder Eiche sind stoßfest und verschleißfest. MDF mit Furnier bietet Stabilität gegen Verziehen. Günstigere Kiefer oder Sperrholz können unter Druck reißen.

Holzauswahl für wiederverwendbare Kisten

| Holzart | Dauerhaftigkeit | Beste Verwendung |

|---|---|---|

| Mahagoni | Sehr stark | Luxuriöse wiederverwendbare Boxen |

| Eiche | Hart und stabil | Hochwertige Aufbewahrungsboxen |

| MDF + Furnier | Kosteneffizient | Dekorative wiederverwendbare Boxen |

| Kiefer/Sperrholz | Schwach, instabil | Nicht zur Wiederverwendung geeignet |

Für ein Zigarrenkistenprojekt in Deutschland entschied sich der Kunde ursprünglich aus Kostengründen für Sperrholz. Nach einem Haltbarkeitstest empfahlen wir spanisches Zedernholz mit MDF-Verstärkung. Diese Kombination bewahrte sowohl die Struktur als auch die Aromaleistung und bewies, dass die Materialauswahl entscheidend ist.

Warum spielen Scharniere, Schlösser und Verbindungsstücke bei Mehrzweck-Holzkisten eine so wichtige Rolle?

Die Hardware ist der am stärksten beanspruchte Teil jeder wiederverwendbaren Box. Eine schlechte Wahl führt zu vorzeitigem Ausfall.

Stabile Scharniere, zuverlässige Schlösser und verstärkte Verbindungen sind für eine reibungslose Funktion und lange Haltbarkeit unerlässlich.

Jedes Öffnen belastet die Scharniere. Jedes Schließen belastet die Schlösser und Verbindungsstellen. Ohne robuste Beschläge versagen Schränke schnell, egal wie schön sie von außen aussehen.

Hardware-Standards

- ScharniereVerwenden Sie Soft-Close-Scharniere aus Messing oder Edelstahl.

- SchlösserWählen Sie langlebige Verschlüsse oder Magnetsysteme, die auf Wiederholungszyklen getestet wurden.

- GelenkeVerwenden Sie Schwalbenschwanz-, Finger- oder verstärkte Gehrungsverbindungen für eine hohe Belastbarkeit.

Eine Bestellung von Uhrenboxen für eine Marke aus dem Nahen Osten scheiterte einmal, weil billige Eisenscharniere verwendet wurden. Nach sechs Monaten beschwerten sich viele Kunden über Rost und kaputte Deckel. Wir ersetzten sie durch Edelstahl-Klavierbandscharniere und lösten damit das Problem. Die Beschläge entscheiden über die langfristige Qualität.

Wie können Innenausstattungsmaterialien (Samt, Leder, Stoff) die Langlebigkeit und Wiederverwendbarkeit beeinflussen?

Innenausstattungen nutzen sich durch den ständigen Kontakt mit Produkten ab. Falsche Materialien nutzen sich schnell ab.

Innenverkleidungen müssen widerstandsfähig gegen Reibung, Feuchtigkeit und wiederholte Beanspruchung sein, um eine langfristige Nutzbarkeit zu gewährleisten.

Samt fühlt sich weich an, aber minderwertiger Samt fusselt mit der Zeit. PU-Leder ist strapazierfähig, kann jedoch bei Feuchtigkeitseinwirkung Risse bilden. Natürliches Wildleder sieht luxuriös aus, ist jedoch empfindlich gegenüber Feuchtigkeit.

Auskleidungsoptionen für wiederverwendbare Boxen

| Material der Auskleidung | Vorteil | Begrenzung |

|---|---|---|

| Hochwertiger Samt | Weicher, eleganter Look | Unter starker Reibung verschleißt |

| PU-Leder | Stark, abwischbar | Kann in feuchten Klimazonen altern |

| Naturwildleder | Luxuriös, hochwertig | Feuchtigkeitsempfindlich |

| Gewebe | Atmungsaktiv, stabil | Weniger luxuriöses Gefühl |

Ich habe einmal eine Serie wiederverwendbarer Schmuckkästchen aus kostengünstigem Samt hergestellt. Nach einem Jahr stellten Kunden Haarausfall fest. Bei der nächsten Charge wechselten wir zu einem Futter aus PU-Leder. Das Feedback verbesserte sich deutlich, was zeigt, wie sich die Wahl des Innenmaterials auf die Wiederverwendbarkeit auswirkt.

Welche Veredelungs- und Beschichtungsverfahren schützen die Schachtel vor Abnutzung, Feuchtigkeit und Kratzern?

Ohne eine hochwertige Oberflächenbehandlung verliert selbst das beste Holz nach wiederholtem Gebrauch an Qualität.

Schutzbeschichtungen wie Lack, PU und natürliche Öle verlängern die Lebensdauer von wiederverwendbaren Holzkisten.

Hochglänzender Klavierlack ist kratzfest und feuchtigkeitsbeständig. Matte PU-Oberflächen bieten zurückhaltende Langlebigkeit. Natürliche Öle schützen die Holzmaserung, erfordern jedoch Pflege.

Optionen für Schutzbeschichtungen

- KlavierlackLuxuriös, äußerst strapazierfähig, aber arbeitsintensiv.

- Mattes PU: Kratzfest, kostengünstig.

- Natürliche Öle: Umweltfreundlich, muss erneut aufgetragen werden.

- UV-BeschichtungVerhindert das Ausbleichen, geeignet für dekorative Schachteln.

Eine Weinbox-Bestellung für einen Kunden aus Großbritannien erforderte eine hohe Wiederverwendbarkeit. Wir verwendeten 12 Schichten Klavierlack mit Handpolitur. Die Oberfläche sah nicht nur hochwertig aus, sondern blieb auch nach jahrelangem Gebrauch kratzfrei.

Wie lässt sich bei der Entwicklung von Produkten für vielfältige Verwendungszwecke ein Gleichgewicht zwischen Umweltfreundlichkeit und Langlebigkeit herstellen?

Kunden legen heute Wert auf Nachhaltigkeit. Aber umweltfreundlich muss auch langlebig bedeuten.

Um Umweltfreundlichkeit und Langlebigkeit in Einklang zu bringen, müssen nachhaltige Hölzer, VOC-arme Oberflächenbehandlungen und recycelbare Beschläge ausgewählt werden, während gleichzeitig die strukturelle Festigkeit gewährleistet sein muss.

Die Verwendung von FSC-zertifiziertem Holz, wasserbasierten Oberflächenbehandlungen und recycelbaren Beschlägen reduziert die Umweltbelastung. Der Verzicht auf strukturelle Verstärkungen im Namen der Umweltfreundlichkeit kann jedoch dazu führen, dass die Box weggeworfen wird, was nicht wirklich nachhaltig ist.

Ausgewogene ökologische Entscheidungen

- FSC-zertifiziertes Mahagoni oder Zedernholz.

- Wasserbasierte PU-Lacke.

- Recycelbare Edelstahl-Hardware.

- Langlebiges Design, das Ersatzabfälle vermeidet.

Ich habe einmal eine Marke in Skandinavien beraten, die “Öko-Verpackungen” wollte. Anstatt Schutzbeschichtungen zu entfernen, haben wir wasserbasierte Lacke und erneuerbares Furnier verwendet. Die Kartons hielten jahrelang, und die Kunden lobten sowohl die Haltbarkeit als auch die ökologischen Werte.

Schlussfolgerung

Wiederverwendbare Holzkisten erfordern eine kluge Materialauswahl, robuste Beschläge, schützende Oberflächenbehandlungen und umweltbewusste Langlebigkeit, um wirklich einen langfristigen Wert zu bieten.

Markenname: WoodoBox

Slogan: Maßgefertigte Holzkisten, handwerklich perfekt gefertigt

Website: www.woodobox.com

WhatsApp: +86 18359265311