Kunden glauben oft, dass ein genehmigtes Muster identische Massenwaren garantiert. In Wirklichkeit führt die Massenproduktion zu Abweichungen.

Die Musterfreigabe bestätigt die Designabsicht, aber ohne strenge Kontrollen kann es bei der Massenproduktion zu Abweichungen in Farbe, Oberfläche oder Montage kommen.

Um diese Lücke zu schließen, sind klare Kommunikation, definierte Toleranzen und eine schrittweise Qualitätskontrolle erforderlich.

Warum können handgefertigte Muster anders aussehen als massengefertigte Artikel?

Muster werden in der Regel von erfahrenen Handwerkern mit besonderer Sorgfalt angefertigt. Die Massenproduktion erfolgt nach wiederholbaren Verfahren.

Handgefertigte Muster wirken oft raffinierter, während Serienprodukte aufgrund maschineller Fertigungsprozesse und Geschwindigkeit geringfügige Abweichungen aufweisen können.

Beispielsweise kann ein Prototyp stundenlang von Hand geschliffen werden, während bei der Massenproduktion Maschinen mit festgelegten Zyklen zum Einsatz kommen. Selbst geringfügige Unterschiede beim Polierdruck führen zu einem unterschiedlichen Glanzgrad.

Häufige Beispiele vs. Massenlücken

- Handaufgetragener Lack sieht glatter aus als gesprühte Schichten.

- Prototyp-Scharniere werden manuell eingestellt, Serien-Scharniere lassen sich schneller montieren.

- Farbtöne erscheinen satter, wenn sie einzeln gemischt werden, als wenn sie in großen Mengen gemischt werden.

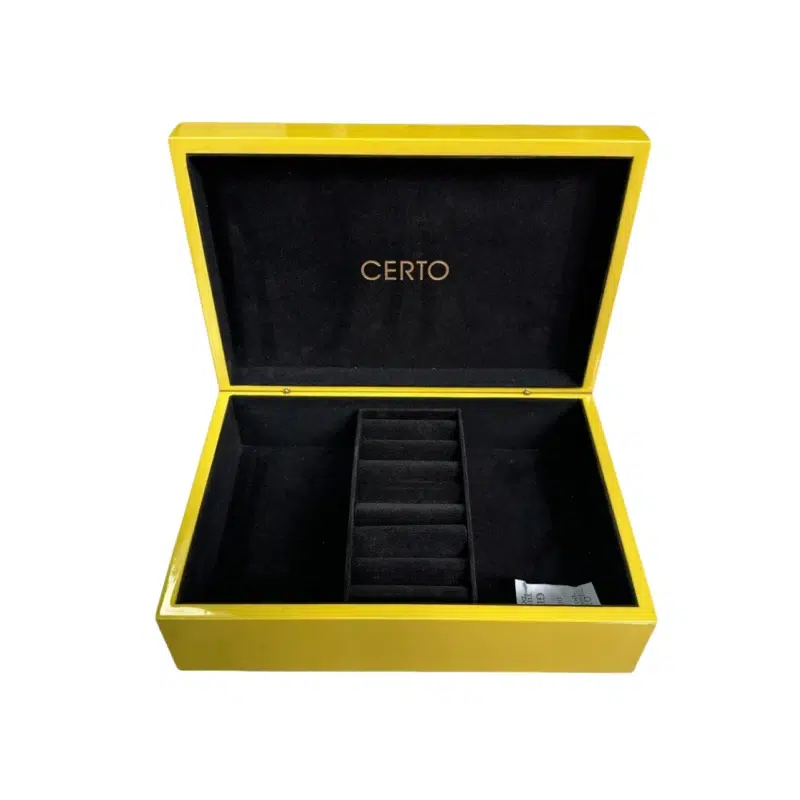

Ich erinnere mich an ein Projekt für eine Schmuckschatulle, bei dem das Muster einen makellosen Klavierlack aufwies. Bei der Massenproduktion war der Glanz etwas weniger intensiv, da die maschinell aufgetragenen Schichten dünner waren. Durch die frühzeitige Erklärung dieser Tatsache konnten Streitigkeiten vermieden werden.

Wie wirken sich Änderungen bei der Materialbeschaffung auf die Konsistenz zwischen Muster- und Großbestellung aus?

Die Materialbeschaffung ist einer der am häufigsten übersehenen Gründe für Unterschiede.

Bei Großbestellungen können Holz, Furnier oder Stoff aus verschiedenen Chargen verwendet werden, was zu geringfügigen Abweichungen gegenüber dem Muster führen kann.

Natürliche Materialien wie Holz und Furnier variieren in Maserung und Farbton. Selbst Metallschlösser können je nach Charge unterschiedliche Farbtöne aufweisen.

Materialvariabilitätsfaktoren

- Unterschiedliche Holzchargen = Abweichungen in Maserung und Klangfarbe.

- Furnierzuschnitte = uneinheitliche Muster.

- Leder- oder Stofffärbepartien = Farbtonunterschiede.

- Hardware-Beschichtung = leichte Farbabweichungen.

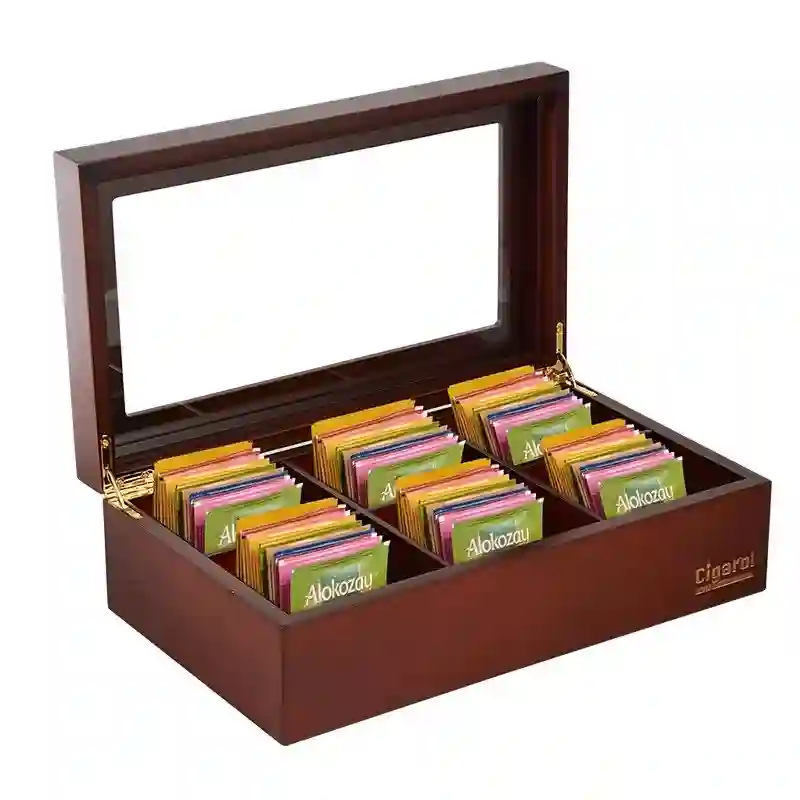

Bei einer Bestellung von Zigarrenkisten hatte das genehmigte Muster ein Furnier aus geradfaserigem Walnussholz. Das Furnier in der Großpackung wies einige Wirbel auf. Das war zwar ganz natürlich, aber der Kunde war überrascht. Diese Erfahrung hat mich gelehrt, immer zu fragen: “Akzeptieren Sie natürliche Abweichungen oder sollen wir das Furnier nach mehr Einheitlichkeit sortieren?”

Welche Herausforderungen bei der Produktion (Farbabweichungen, Details der Endbearbeitung, Montagenauigkeit) treten häufig bei der Serienfertigung auf?

Skalierung vergrößert kleine Probleme. Was in einem Stück einfach aussieht, wird in Hunderten schwieriger.

Zu den Herausforderungen bei der Massenproduktion zählen Farbabweichungen, ungleichmäßiger Lackauftrag und kleine Fehlausrichtungen bei der Montage.

Selbst bei sorgfältiger Planung ist es schwierig, die Beschichtungskonsistenz über Hunderte von Kartons hinweg aufrechtzuerhalten. Auch kann es zu geringfügigen Abweichungen beim Anpressdruck kommen, den die Arbeiter beim Anbringen von Verbindungsstücken oder Scharnieren ausüben.

Häufige Produktionsprobleme

- Farbe: Die Lackfarbtöne variieren zwischen den Chargen.

- OberflächeDer Glanzgrad variiert je nach Trocknungsbedingungen.

- Montage: Scharniere oder Deckel leicht verschoben.

- LogoDer Stanzdruck ist nicht bei jedem Stück identisch.

Ich habe einmal 800 Uhrenboxen mit Hochglanzlack hergestellt. Eine regnerische Woche veränderte die Trocknungszeiten, was zu leichten Glanzunterschieden führte. Durch frühzeitige Kommunikation über mögliche Abweichungen konnten die Erwartungen des Kunden gesteuert werden.

Warum ist es wichtig, Toleranzstandards und akzeptable Abweichungen im Voraus festzulegen?

Ohne klare Toleranzregeln können selbst kleinste Unterschiede zu Streitigkeiten führen.

Durch die Festlegung von Toleranzstandards wird klargestellt, welche Abweichungen akzeptabel sind und welche nicht, wodurch spätere Konflikte vermieden werden.

Luxuskunden erwarten Perfektion, aber 100% identische handgefertigte Oberflächen sind unrealistisch. Toleranzvereinbarungen schaffen Fairness.

Beispiel Toleranzstandards

| Aspekt | Zulässige Abweichung |

|---|---|

| Farbton | ±5% Farbtonunterschied bei Tageslicht |

| Logo-Position | ±1 mm Fehlausrichtung |

| Furniermaserung | Natürliche Variation innerhalb ausgewählter Arten |

| Glanzgrad | Konsistent innerhalb einer Glanzstufe |

Bei einem Projekt im Nahen Osten haben wir im Voraus vereinbart, dass die Toleranz für die Platzierung des Logos ±1 mm beträgt. Als die Qualitätskontrolle geringfügige Abweichungen feststellte, akzeptierte der Kunde diese ohne Probleme, da die Erwartungen festgelegt waren.

Wie kann eine klare Dokumentation (Zeichnungen, Spezifikationen, QC-Checklisten) Missverständnisse minimieren?

Dokumentation verwandelt verbale Erwartungen in messbare Standards.

Zeichnungen, Spezifikationen und QC-Checklisten liefern einen schriftlichen Nachweis der getroffenen Vereinbarungen und reduzieren so subjektive Interpretationen.

Anhand detaillierter Zeichnungen und Muster der Oberflächenbeschaffenheit kennt jeder Arbeiter und Inspektor das Ziel. Ohne diese Informationen bleiben Begriffe wie “Premium” oder “Luxus” vage.

Wichtige Dokumentationswerkzeuge

- Technische Zeichnungen mit genauen Abmessungen.

- Vom Kunden unterzeichnete Muster oder Farbtafeln fertigstellen.

- Schriftliche QC-Checkliste mit Prüfpunkten.

- Fotografische Referenzen des genehmigten Musters.

Für eine limitierte Weinkartonserie habe ich ein QC-Blatt mit 20 Prüfpunkten erstellt, von der Furnierausrichtung bis zum Glanzgrad. Sowohl der Kunde als auch die Fabrik haben es unterzeichnet. Dieses eine Dokument hat zukünftige Streitigkeiten vermieden.

Welche Rolle spielt die schrittweise Qualitätsprüfung bei der Anpassung von Schüttgütern an das genehmigte Muster?

Die abschließende Qualitätskontrolle ist wichtig, aber eine schrittweise Überprüfung beugt Problemen frühzeitig vor.

Eine schrittweise Überprüfung stellt sicher, dass jede Phase – Schneiden, Montage, Beschichtung, Branding – mit dem Muster übereinstimmt, bevor es weitergeht.

Wenn Probleme frühzeitig erkannt werden, lassen sie sich kostengünstiger und schneller beheben. Das Warten bis zur abschließenden Qualitätskontrolle führt oft zu Produktverschwendung.

Schritt für Schritt QC-Fokus

- MaterialprüfungÜberprüfen Sie den Furnierton vor dem Schneiden.

- Montageprüfung: Stellen Sie sicher, dass die Verbindungsstellen und Scharniere ausgerichtet sind.

- BeschichtungsprüfungVergleichen Sie den Glanz nach jeder Schicht.

- Markenprüfung: Bestätigen Sie die Größe und Position des Logos.

- Endkontrolle: Das Gesamtbild muss mit dem genehmigten Muster übereinstimmen.

Bei einem Projekt haben wir nach der vierten Lackschicht eine Pause eingelegt, um Fotos vom Glanzgrad zu schicken. Der Kunde wünschte sich mehr Tiefe. Durch diese Anpassung während des Prozesses mussten wir später nicht Hunderte von Kisten neu polieren.

Schlussfolgerung

Die Musterfreigabe zeigt die Designabsicht, aber nur definierte Toleranzen, Dokumentation und schrittweise Qualitätskontrolle stellen sicher, dass die Massenproduktion den Erwartungen entspricht.

Markenname: WoodoBox

Slogan: Maßgefertigte Holzkisten, handwerklich perfekt gefertigt

Website: www.woodobox.com

WhatsApp: +86 18359265311