Personalization makes luxury packaging feel alive. But when orders scale, small details can become bottlenecks if not handled with care.

Personalized elements like numbering, signatures, and codes can be integrated into mass production, but only with the right technology, workflow planning, and quality control.

I have seen personalization transform wooden boxes into collector’s items. Yet I have also witnessed chaos when accuracy management was overlooked.

Why do personalized details greatly enhance exclusivity and brand storytelling?

Luxury buyers expect more than wood and hinges. They want a story.

Personalized details add exclusivity because they connect directly with brand storytelling and make each box feel unique.

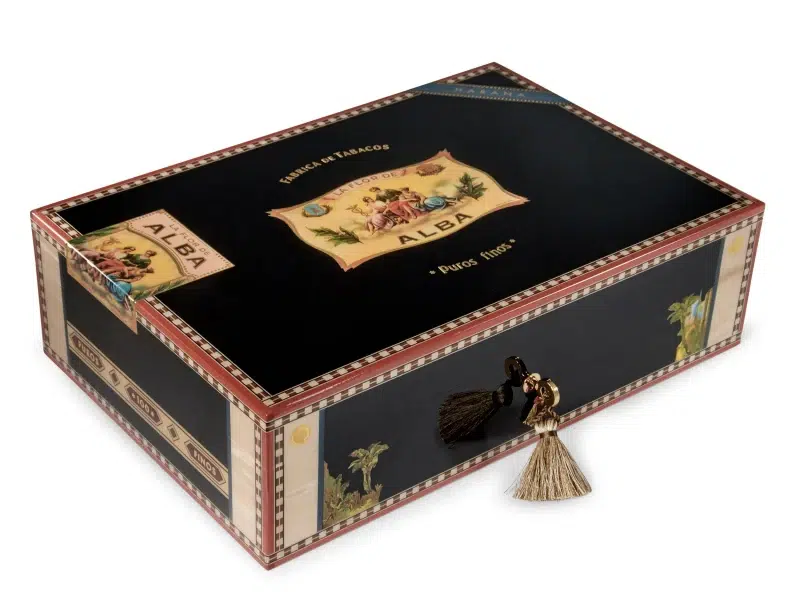

Numbering systems, engraved names, or limited-edition codes tell collectors that this box is not mass-produced—it is part of a rare set. Customers feel ownership of a piece of history.

These details also enhance storytelling. A cigar box numbered “No. 25 of 200” is more than packaging—it is evidence of rarity. A client’s engraved signature reinforces authenticity. Limited-edition codes create trust and make resale value stronger.

Personalization as storytelling

- Numbering proves rarity

- Signatures add authenticity

- Codes build brand narrative

I recall a cigar brand that engraved each box with its buyer’s initials. Customers proudly shared photos online, which boosted the brand’s reputation. That emotional link came entirely from personalization.

How can numbering systems (e.g., 001/500) be embedded without disrupting workflow?

Sequential numbering looks simple but can break efficiency if not planned.

Numbering systems should be embedded through automated or semi-automated processes that fit naturally into the production line.

The cleanest method is laser engraving at the final stage. Numbers can be batch-fed into the machine, and the process takes seconds per box. Another option is UV printing, which applies ink directly onto wood or lacquer.

For metal plaques, numbering can be pre-printed on plates and then attached during assembly. This approach avoids late-stage errors.

Numbering integration methods

| Technik | Best stage | Anmerkungen |

|---|---|---|

| Lasergravur | Final finishing | Fast, permanent |

| UV-Druck | After lacquer | High precision |

| Metalltafeln | Assembly | Flexible, replaceable |

In one 1,000-box project, we engraved sequential numbers in one session using pre-programmed files. The process added only one day to the schedule, without disrupting the flow.

What techniques (laser engraving, UV printing, metal plaques) are best for mass personalization?

Not all personalization tools perform equally.

Laser engraving, UV printing, and metal plaques each have strengths for different scales and finishes.

Laser engraving is permanent and precise. It works best on wood and lacquer surfaces. UV printing offers color flexibility, so logos or codes can appear in gold, silver, or brand-specific shades. Metal plaques give a luxurious look and are replaceable if errors occur.

Technischer Vergleich

| Methode | Profis | Nachteile | Best use |

|---|---|---|---|

| Lasergravur | Permanent, precise | Limited to monochrome | Sequential numbers, signatures |

| UV-Druck | Full-color, fast | Less durable on rough wood | Logos, QR codes |

| Metalltafeln | Luxury feel, replaceable | Higher cost | Limited editions, premium branding |

I often advise luxury clients to combine methods. For example, laser engraving for numbering, and a metal plaque for branding. This layered effect reinforces exclusivity while keeping production efficient.

How does personalized customization impact production speed and quality consistency?

Adding personalization introduces extra steps. If poorly managed, it slows everything down.

Personalized customization impacts speed and consistency, but with automation and clear workflow separation, the effects can be minimized.

When done manually, personalization creates bottlenecks. Workers spend time checking lists, aligning engravings, and preventing mistakes. Automation helps: engraving files can be batch-prepared, and UV printers can run with preloaded data.

Consistency is also a challenge. One misprinted code can ruin a collector’s trust. Dedicated QC checkpoints are required after personalization to avoid sending flawed units.

Workflow strategies

- Automate data input for numbering and codes

- Separate personalization into a late-stage process

- Add 100% QC inspection step before packaging

For one limited edition run, we handled personalization in a dedicated small workshop, separate from mass production. This protected the main workflow while ensuring every piece was checked individually.

What risks arise in accuracy management when handling client-specific signatures or codes?

The biggest risk in personalization is human error.

Managing accuracy for signatures and codes is risky because mistakes create irreplaceable defects and damage brand trust.

If a client’s name is misspelled, or if two boxes share the same limited-edition number, the error cannot be corrected without replacement. For luxury goods, such mistakes are unacceptable.

Personalized codes also require strict data handling. If the engraving team receives outdated or incorrect files, the entire batch may carry wrong numbers.

Accuracy risks

- Misspelled signatures

- Duplicate numbering

- Incorrect code sequencing

I once witnessed a competitor produce two boxes with the same number in a 300-piece series. Collectors noticed quickly, and the brand faced embarrassment. This shows how vital data management is in personalization.

How can digital tracking and quality control ensure smooth integration of personalization in large orders?

Technology can prevent most errors if applied correctly.

Digital tracking systems and layered QC ensure smooth personalization integration, even for large-volume orders.

A digital database can link each serial number or signature to its specific box. When engraving or printing, the machine pulls directly from this database. This reduces manual input and mistakes.

QC teams should verify personalization at multiple checkpoints: right after engraving/printing, before assembly, and at final packaging. A barcode or QR system can also confirm that each unique element matches the client’s order.

Control system outline

- Centralized database for codes and numbers

- Automated engraving/printing file generation

- QC inspection after personalization stage

- Digital verification at packaging

In one large order of 5,000 watch boxes, we used QR-coded labels tied to a master spreadsheet. Every engraved number matched its digital record. The process ran smoothly, with zero duplication or errors.

Schlussfolgerung

Personalization can scale in wooden box production if supported by the right technology, workflow, and QC. It enhances exclusivity while protecting efficiency and accuracy.

Markenname: WoodoBox

Slogan: Maßgefertigte Holzkisten, handwerklich perfekt gefertigt

Website: www.woodobox.com

WhatsApp: +86 18359265311