I see many buyers lose time and money because factory communication feels confusing and risky. The real pain is not cost. It is uncertainty and rework.

Buying wooden cigar boxes directly from a manufacturer works when you treat it as a small manufacturing project, not a product order. Structure, clarity, and control decide the result.

I learned this the hard way. After years inside factories, I now see the same pattern every time. Buyers who prepare well succeed. Buyers who guess struggle. Let me show you how to do this the right way.

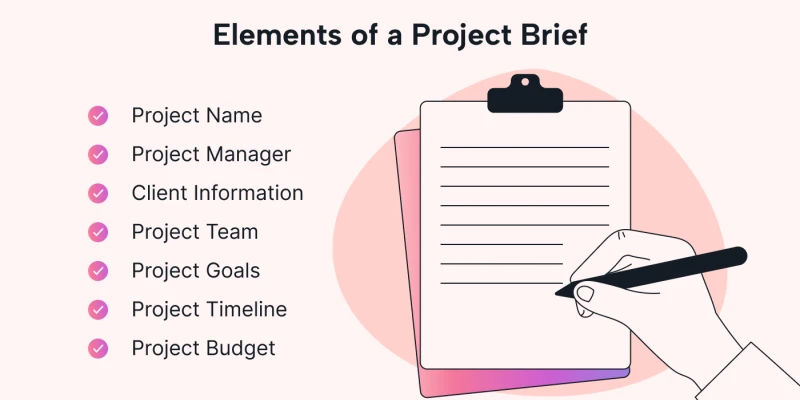

Turn “I want a custom cigar box” into a factory-executable project brief

Many buyers feel stuck at the first message. They want a custom cigar box, but factories keep asking questions. The problem is not language. The problem is missing structure.

A factory can only execute what is clearly defined. A clear brief turns uncertainty into a controlled production task.

The 10 items you must prepare before contacting a factory

I always tell clients this list is not optional. Each item removes a risk point.

| Artikel | Warum es wichtig ist |

|---|---|

| Number of cigars | Defines inner size and cedar usage |

| Target retail price | Sets material and finish ceiling |

| Visual references | Aligns expectations fast |

| Outer material choice | Controls stability and cost |

| Cedar requirement | Affects aroma and compliance |

| First order quantity | Directly affects MOQ |

| Annual potential | Impacts factory priority |

| Launch timeline | Limits finish complexity |

| Sales market | Decides moisture strategy |

| Top 3 priorities | Guides trade-off decisions |

Why factories ask these questions

Factories do not ask to slow you down. They ask because every answer changes tooling, labor flow, and risk.

When you skip these details, any quote you receive is only a guess. Guessing always becomes expensive later.

My personal rule for briefs

I write my brief as if the factory never met me. If someone else inside the factory reads it, they should still understand the project.

That is the standard.

The complete material system of cigar boxes: you are choosing risk, not just wood

Buyers often focus on “premium wood.” That focus is dangerous. The real issue is not luxury. It is stability.

Most cigar box failures come from wrong material combinations, not cheap materials.

Understanding exterior material choices

Solid wood exterior

- Strong natural texture

- High sensitivity to humidity

- Higher deformation risk in cross-border shipping

Veneered MDF exterior

- Controlled structure

- Strong dimensional stability

- Better for global markets

Cedar lining is not negotiable detail

Spanish cedar is not only about smell. It controls humidity and protects cigars.

| Cedar Thickness | Risikostufe |

|---|---|

| < 2 mm | Warping and cracking |

| 2-3 mm | Industry-proven safe zone |

| > 3 mm | Cost rises sharply |

Moisture balancing is invisible but critical

Before mass production, we always balance wood moisture. Without this step, boxes made in China will react badly when shipped to Europe or the Middle East.

This step costs time, but it saves projects.

How I explain material choices to clients

I never ask, “Do you want premium?”

I ask, “Where will this box live, and for how long?”

That answer decides materials.

Structure and tolerance control: most mass-production problems are decided at the drawing stage

A cigar box can look perfect and still fail after six months. Structure decides lifespan.

Structure is the life design of a cigar box.

Key structural parameters that must be locked

| Parameter | Typical Options |

|---|---|

| Lid angle | 90°, 105°, 110° |

| Limit stop | Yes / No |

| Hinge type | Standard / Soft-close / Hidden |

| Lid gap | 0,6-0,8 mm |

Why tolerance control matters

If hinge installation deviates more than 0.5 mm, the lid will bind or loosen over time. This is not theory. I see it often.

Factories can control tolerance, but only if targets are clear in drawings.

Drawings are not decoration

Many buyers approve drawings without reviewing tolerances. That is a mistake.

I always check:

- Hinge alignment notes

- Gap callouts

- Assembly sequence notes

A simple mindset shift

If it is not written in the drawing, it does not exist in production.

That rule saves money.

The real formula behind pricing, MOQ, and lead time inside factories

MOQ feels like a wall to many buyers. It is not. It is a formula.

MOQ exists because factories optimize for stable production, not small experiments.

Why MOQ is usually 500–1,000 pcs

| Cost Driver | Auswirkungen |

|---|---|

| Paint line changeover | Fixed setup cost |

| Jigs and tooling | One-time investment |

| Labor learning curve | Efficiency loss at low volume |

Below MOQ, factories do not earn less. They transfer risk to you through higher unit cost.

Understanding lead time honestly

Lead time is not just production days. It includes:

- Material preparation

- Moisture balancing

- Sampling feedback loops

- Packaging tests

How I negotiate MOQ realistically

I do not argue MOQ. I explain my annual potential and launch plan. That changes the conversation.

Factories think long-term. Buyers should too.

From sampling to mass production: 12 control points buyers must lock in

Sampling is not about approval. It is about locking standards.

A golden sample is a contract, not a reference.

The 12 checkpoints I never skip

| Checkpoint | Warum es wichtig ist |

|---|---|

| Farbkonsistenz | Prevents batch mismatch |

| Lid smoothness | User experience |

| Hinge rebound | Long-term performance |

| Lid gap | Visual quality |

| Cedar burrs | Product safety |

| Cedar aroma | Authentizität |

| Logo edges | Image der Marke |

| Insert stability | Shipping safety |

| Fingerprint resistance | Retail handling |

| Packaging strength | Transport survival |

| Falltest | Real-world damage |

| Golden sample rule | Quality enforcement |

Lighting matters more than you think

I always check color under natural and warm light. Many finishes pass one and fail the other.

The golden sample rule

I write this clearly:

“Golden sample = mass production standard.”

Without this sentence, disputes become emotional.

Why this step separates pros from beginners

Factories respect buyers who control standards. Clear buyers get clear execution.

Schlussfolgerung

Factory-direct sourcing works when you lead with structure, not price. Clear information turns factories into reliable partners.

WoodoBox – Premium Wooden Packaging Manufacturer in China

Maßgefertigte Holzkisten, handwerklich perfekt gefertigt