Perfume leakage ruins products, damages brand trust, and creates costly disputes. Many brands blame bottles or pumps, but the real causes usually hide inside shipping conditions and packaging choices.

Perfume leakage during overseas shipping is caused by pressure, temperature, movement, and weak packaging systems working together, not by a single defective part.

I have worked with perfume brands for over 15 years. From my experience, leakage is not random. It follows clear physical rules. Once you understand those rules, you can control them.

This article breaks down the real causes behind perfume leakage and explains how overseas packaging decisions either prevent or trigger the problem.

How do pressure and altitude changes during air and sea transport trigger leakage?

Pressure changes during overseas shipping silently stress perfume bottles long before they reach the customer. Many brands never consider this factor until leakage appears.

Pressure differences between the inside and outside of the bottle push liquid toward the spray system, forcing leakage when packaging does not buffer the change.

Why pressure change matters in overseas shipping

When perfume is filled and sealed, the air inside the bottle is trapped at ground-level pressure. During air freight, the aircraft climbs rapidly. External air pressure drops. Internal pressure stays higher.

This creates outward force.

That force pushes directly on:

- The spray pump

- The crimp area

- The internal gasket

Even small pressure differences act continuously during long flights. The pump does not fail immediately. Instead, it weakens over time.

Sea freight creates a different issue. Containers experience slow pressure variation due to weather systems, port altitude differences, and container sealing conditions. The effect is weaker than air freight, but the exposure time is much longer.

Why pumps alone cannot solve pressure problems

Many brands try to fix leakage by upgrading spray pumps. This often fails.

The reason is simple. Pumps are designed for daily use pressure changes, not for extreme altitude shifts or sealed container environments.

From my investigations, leakage often happens with:

- High-quality pumps

- Well-crimped bottles

- Perfect lab test results

The missing element is pressure buffering.

How packaging controls pressure stress

Packaging acts as the first defense layer. A rigid outer structure slows how fast pressure changes reach the bottle.

Here is a simple comparison from projects I handled:

| Verpackungsart | Pressure Transfer Speed | Leakage Risk |

|---|---|---|

| Thin carton | Instant | Hoch |

| Foam-only box | Schnell | Mittel |

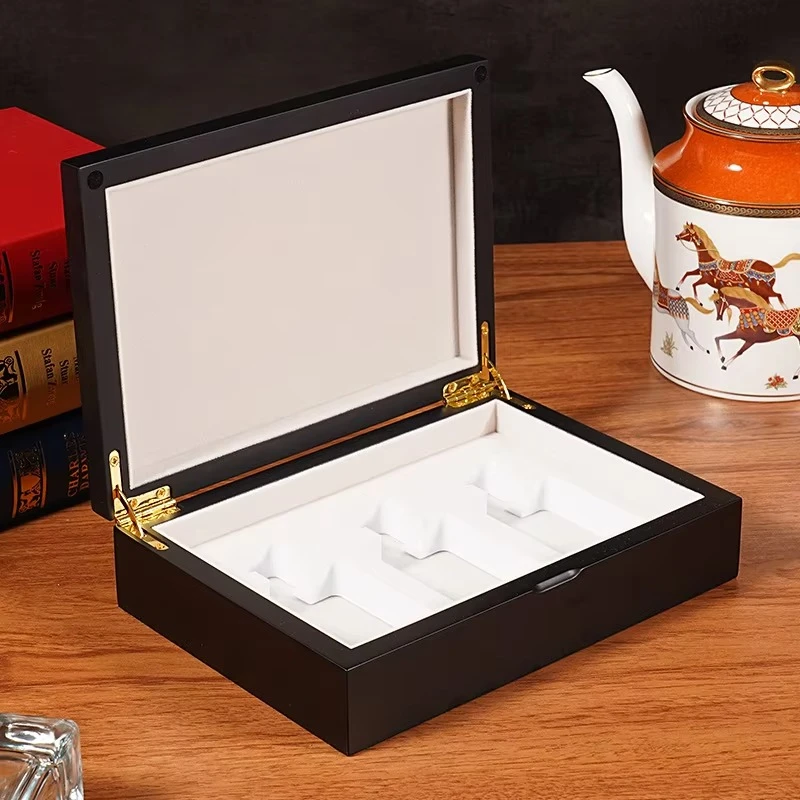

| Rigid wooden box | Langsam | Niedrig |

Wooden boxes do not stop pressure change. They delay it. That delay reduces peak stress on the pump and seal.

In several air freight projects, we reduced leakage complaints by more than 70% by switching only the outer packaging. The bottle and pump stayed the same.

Why are the spray pump and bottle neck the weakest points in overseas shipping?

Every perfume bottle has natural weak points. During overseas shipping, these weak points receive repeated stress.

The spray pump and bottle neck fail first because they combine mechanical joints, soft materials, and pressure exposure in one small area.

Understanding the structure of a perfume bottle

A perfume bottle looks solid, but its sealing system is complex.

Key components include:

- Glass bottle neck

- Pump stem

- Crimped metal collar

- Internal gasket

- Actuator cap

All these parts meet at one location.

This area must:

- Hold liquid

- Allow air exchange during spraying

- Survive vibration and pressure

That is a difficult balance.

Why vibration targets the neck area

During shipping, cartons move constantly. Trucks vibrate. Containers roll. Forklifts tilt.

If the bottle moves inside the box, that movement focuses stress on the neck. Even tiny motion creates leverage.

I often explain this to clients using a simple idea. A bottle standing loose in a box behaves like a hammer hitting its own seal again and again.

Over weeks of transport, this causes:

- Micro-gaps in the gasket

- Crimp relaxation

- Pump stem misalignment

None of these are visible at first.

Why leakage appears without visible damage

One common complaint I hear is, “The bottle looks perfect, but it leaked.”

This is normal.

Leakage does not require cracks. It needs only a microscopic path.

Here are typical invisible failures I find:

- Gasket compression loss

- Crimp deformation by vibration

- Pump stem tilt by repeated side pressure

Once liquid finds a path, capillary action does the rest.

Packaging’s role in protecting the neck

The goal of packaging is not cushioning alone. It is immobilization.

Effective packaging must:

- Lock the bottle in position

- Prevent rotation

- Absorb vibration before it reaches the neck

Rigid wooden inner frames perform well here. They create fixed contact points and spread force over a larger area.

In my experience, when the bottle cannot move, the pump survives.

How do temperature fluctuations increase internal pressure and evaporation?

Temperature changes are one of the most underestimated causes of perfume leakage.

Heat increases vapor pressure inside the bottle, and repeated heating and cooling cycles slowly push liquid through the spray system.

What happens inside a perfume bottle when temperature changes

Perfume contains alcohol and aromatic compounds. These are volatile.

When temperature rises:

- Liquid expands

- Alcohol vapor pressure increases

- Internal pressure climbs

When temperature drops:

- Pressure decreases

- Air contracts

During overseas shipping, bottles experience this cycle many times.

Examples include:

- Hot port storage

- Cold night transport

- Air-conditioned warehouses

- Tropical container exposure

Each cycle acts like a small pump.

Why evaporation leads to leakage, not just loss

Many people think evaporation only causes fragrance loss. In reality, evaporation creates pressure.

That pressure pushes vapor and liquid toward the weakest exit. That exit is the spray system.

Over time, liquid reaches:

- The pump chamber

- The stem channel

- The cap interior

From there, gravity and movement complete the leak.

Why long-distance shipping amplifies the effect

Domestic transport may expose bottles to one or two temperature shifts. Overseas shipping exposes them to dozens.

I once worked on a case where leakage only appeared after 45 days at sea. Short tests showed nothing.

This pattern is common.

How packaging reduces temperature shock

Packaging cannot control temperature, but it can slow change.

Here is how different materials behave:

| Packaging Material | Thermal Response Speed | Leakage Protection |

|---|---|---|

| Thin paperboard | Sehr schnell | Niedrig |

| Plastic foam | Schnell | Mittel |

| Holzkiste | Langsam | Hoch |

Wood has natural insulation properties. It delays heat transfer. This reduces peak pressure spikes.

In export projects where temperature fluctuation was severe, wooden packaging consistently reduced leakage even without changing logistics routes.

Why does inadequate internal fixation lead to seal failure over long distances?

Movement is the silent killer of perfume seals.

When bottles move inside the box, repeated micro-motion weakens seals and creates leakage paths over time.

Why small movement causes big problems

Many brands assume a tight-looking fit is enough. It is not.

Even a few millimeters of space allows:

- Tilting

- Rotational motion

- Impact against inner walls

Each movement transfers force to the bottle neck.

Over thousands of kilometers, these small forces add up.

Common internal fixation mistakes I see

From audits and failure analysis, the same mistakes appear again and again:

- Single-layer foam without structural support

- Over-soft cushioning

- Loose partitions

- Incorrect cavity size

Soft materials absorb shock but allow motion. This is a key misunderstanding.

What proper fixation really means

Good fixation does not mean soft. It means controlled.

Effective fixation systems:

- Hold the bottle at fixed points

- Prevent rotation

- Distribute load evenly

I often recommend hybrid systems. These combine:

- Rigid structure for positioning

- Soft layers for shock absorption

Example of fixation performance

| Fixation Type | Bottle Movement | Leakage Risk |

|---|---|---|

| Loose foam | Hoch | Hoch |

| Molded pulp | Mittel | Mittel |

| Wooden inner frame | Sehr niedrig | Niedrig |

In almost every leakage case I investigated, improving fixation solved the issue without touching the bottle design.

How does packaging choice determine whether leakage happens or not?

Packaging is not decoration. It is a protection system.

The right packaging controls pressure, temperature, and movement at the same time, which directly determines whether leakage occurs.

Why thin cartons fail in overseas shipping

Thin cartons are designed for retail display, not logistics stress.

They:

- Transmit vibration directly

- Respond instantly to pressure changes

- Offer no thermal buffering

They also deform easily, which transfers force inward.

Why foam-only solutions are incomplete

Foam solves one problem but creates another.

It absorbs shock, but it allows movement. It also reacts quickly to temperature.

Foam alone cannot stabilize the bottle neck.

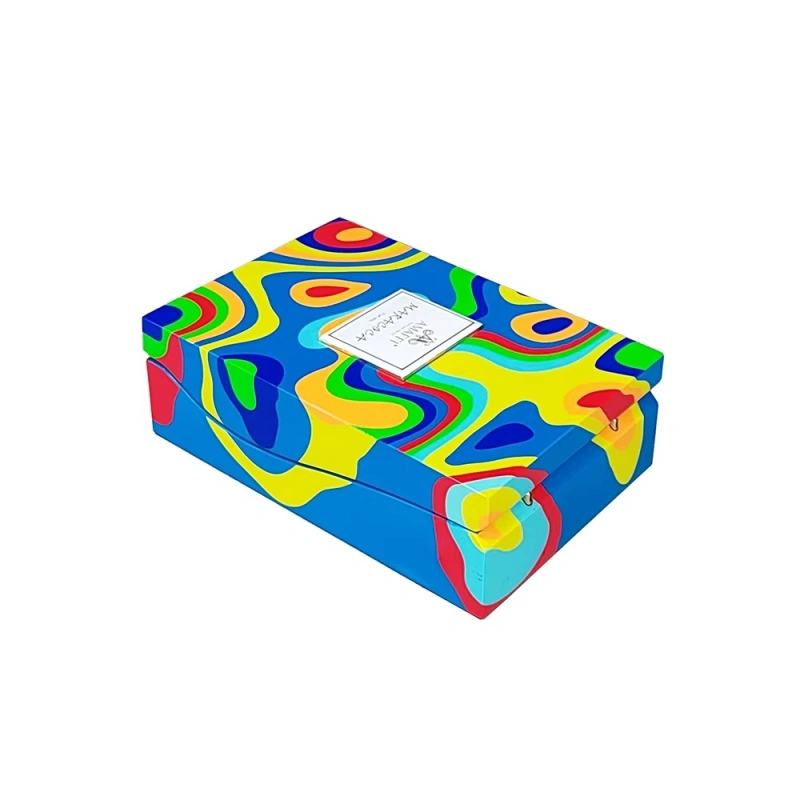

Why wooden packaging performs differently

Wood behaves differently from paper and plastic.

Key advantages include:

- Structural rigidity

- Slow thermal response

- Vibration damping

- Long-term shape stability

In export projects I supported, switching to wooden outer boxes reduced leakage complaints dramatically. We did not change:

- Bottle supplier

- Pump supplier

- Filling process

Only packaging changed.

Packaging as a system, not a box

The most important mindset shift is this.

Packaging must be treated as part of the product system.

It must:

- Work with the bottle

- Support the pump

- Protect during the entire journey

When brands invest here, leakage stops being a mystery.

Schlussfolgerung

Perfume leakage during overseas shipping is predictable. When packaging controls pressure, temperature, and movement, leakage stops being a recurring problem.

Markenname: WoodoBox

Slogan: Maßgefertigte Holzkisten, handwerklich perfekt gefertigt