Ein schönes Schmuckkästchen kann durch eine einzige Naht mit Blasen oder losem PU-Leder ruiniert werden.

Aus diesem Grund ist die Wahl des Klebstoffs nicht nur eine technische Frage - sie bestimmt das visuelle und haptische Erlebnis.

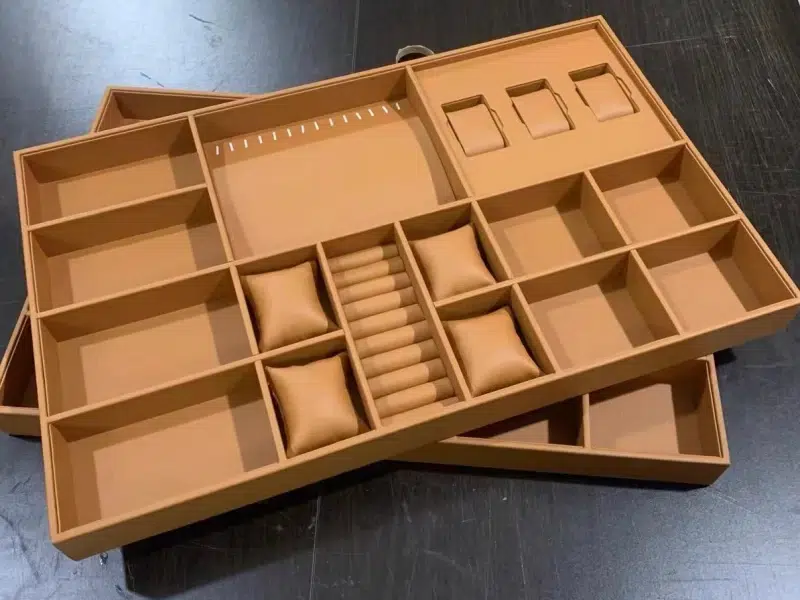

Im Laufe der Jahre habe ich an zahllosen Projekten für Luxus-Schmuckkästchen gearbeitet, und das größte Problem, das Kunden unterschätzen, ist die Qualität des Klebstoffs. Lassen Sie uns die besten Klebepraktiken für langlebige, nahtlose PU-Lederapplikationen erkunden, insbesondere auf komplizierten Oberflächen.

Warum ist die Wahl des Klebstoffs für die langfristige Verklebung von PU-Leder entscheidend?

PU-Leder ist ein synthetisches Material mit einem Träger auf Kunststoffbasis, das sich anders verhält als natürliches Leder oder Stoff. Es:

- Erfordert hochklebrige Klebstoffe1 für dauerhaften Halt

- Ist anfällig für Oberflächenblasenbildung2 wenn die Klebstoffe nicht kompatibel sind

- Kann mit der Zeit delaminieren falsche Leimformel3

- Mai zeigen Flecken oder Verfärbungen wenn der Klebstoff zu aggressiv ist

| Art des Klebstoffversagens | Sichtbare Auswirkungen auf die Schmuckschatulle |

|---|---|

| Abheben oder Schälen der Kanten | Mangelhaftes Handwerk |

| Blasenbildung an der Oberfläche | Billigeres Aussehen |

| Klebeblutungen oder Flecken | Ruiniert die innere Ästhetik |

| Schwache Haftung in Kurven | Reduziert die Langlebigkeit |

✔ Bei Luxusverpackungen muss die Klebeleistung den Anforderungen die Präzision des Kastendesigns selbst.

Welches sind die effektivsten Klebstofftypen für gebogene und komplizierte Oberflächen?

Nicht alle Klebstoffe eignen sich für 3D-Konturen oder empfindliche PU-Träger. Hier sind die zuverlässigsten Klebstofftypen, die ich aufgrund von Praxistests verwende:

1. Kontaktzement auf Lösungsmittelbasis

- Hervorragende Anfangshaftung und langfristiger Halt

- Ideal für enge Kurven und Ecken4

- Trocknet schnell - am besten bei fachgerechter Anwendung

2. PU-Klebstoffe auf Wasserbasis5

- Sicherer für die Arbeitnehmer und umweltfreundlich

- Langsamere Haftzeit ermöglicht bessere Ausrichtung

- Beschädigung von Schaumstoff oder Faserplattenkern weniger wahrscheinlich

3. PU-Schmelzklebstoff6 (für die Automatisierung)

- Verwendet in CNC-ummantelten Innenräumen

- Saubere, starke Verbindung - erfordert jedoch eine hitzebeständige Unterlage

| Kleber Typ | Bester Anwendungsfall | Vorsicht Punkt |

|---|---|---|

| Lösungsmittelkontaktkleber | Scharfe Ecken, strukturelle Verbindungen | Muss die Dämpfe ablüften |

| PU-Kleber auf Wasserbasis | Flache Platten, atmungsaktive Rückseite | Langsameres Trocknen - benötigt Druckzeit |

| Heißschmelzkleber (PU) | Robotische/automatische Verpackung | Kann dünnes PU bei Überhitzung verformen |

✔ Ich habe oft Mischtechniken-Kontaktkleber für detaillierte Kanten, Kleber auf Wasserbasis für große Platten.

Wie vermeidet man das Austreten von Klebstoff oder Blasenbildung bei der Verarbeitung?

Selbst der beste Klebstoff kann Probleme verursachen, wenn er übereilt oder inkonsequent aufgetragen wird.

Bewährte Praktiken:

- Verwenden Sie eine Rolle oder einen feinzahnigen Klebepinsel für gleichmäßige Verteilung

- Anwenden einer dünne, gleichmäßige Schicht auf beiden Oberflächen

- Erlauben Sie Wendezeit bevor die PU in Form gepresst wird

- Verwenden Sie Pressformen oder Werkzeuge für gebogene Kanten um gleichmäßig Druck auszuüben

- Vermeiden Sie es, PU-Leder zu stark zu dehnen, da dies den Kleber aus seiner Position zieht.

| Irrtum | Daraus resultierendes Problem |

|---|---|

| Überkleben | Sickerwasser entlang der Nähte |

| Sofortige Bindung | Verursacht Blasenbildung durch eingeschlossene Dämpfe |

| Ungleichmäßiger Druck | Uneinheitliche Haftung und Oberflächenrippel |

✔ Meine persönliche Regel: jede neue Charge von PU-Leder mit Klebstoff an einem kleinen Muster testen-Werkstoffe variieren geringfügig zwischen den Losen.

Welche Faktoren beeinflussen die Trocknungszeit und die Verarbeitbarkeit bei detaillierten Innenverkleidungen?

Sie brauchen Zeit, um Nähte, Ecken und Falten zu bearbeiten, aber Sie wollen nicht ewig warten. Die Trocknungszeit wird beeinflusst durch:

- Luftfeuchtigkeit und Temperatur der Umgebung7

- Dicke der Leimschicht8

- Material des Substrats9 (Holz absorbiert schneller als ein Kunststoffkern)

- Luftstrom in der Werkstatt

| Umwelt | Einfluss auf die Verarbeitbarkeit des Klebstoffs |

|---|---|

| Hohe Luftfeuchtigkeit | Langsamere Trocknung, schwächeres Anlagerisiko |

| Heißes/trockenes Klima | Kleber blitzt zu schnell ab |

| Geringe Belüftung | Inkonsistente Trocknung |

✔ In den meisten Fällen sind wir Innenräume 12-24 Stunden lang pressen mit leichten Gewichten, um eine gleichmäßige Verklebung zu gewährleisten.

Wie kann man eine starke Haftung gewährleisten, ohne empfindliche Auskleidungsmaterialien zu beschädigen?

Einige PU-Innenausstattungen sind hinterlegt mit Faserpapier, Schwamm oder Mikrofaserdie durch aggressive Klebstoffe beschädigt werden können.

Lösungen:

- Wählen Sie VOC-arme Klebstoffe auf Wasserbasis für empfindliche Beläge

- Verwenden Sie Testpatches auf Faltenbildung oder Flecken zu prüfen

- Anwenden einer Sperrgrundschicht auf porösem MDF oder Holzuntergrund vor dem Verkleben

- Vermeiden Sie übermäßige Hitze während der Verklebung - dies kann den Schaumstoff verformen oder die Maserung anheben.

✔ Kleber immer anpassen Viskosität und pH-Wert auf die Weichheit des Materials - harte Rezepturen lassen weiches PU mit der Zeit schrumpfen.

Welche Testmethoden helfen, die Haltbarkeit und ein sauberes, luxuriöses Finish zu bestätigen?

Bevor ich in die volle Produktion gehe, teste ich immer 3-5 Musterkartons unter realen Bedingungen.

Wesentliche Qualitätskontrollen:

- Peel-Test10: Druck ausüben, dann nach 24 Stunden ziehen

- Hitzeeinwirkung11: Simulieren Sie 40°C, um die Lieferung im Sommer nachzuahmen.

- Kanteninspektion: Prüfen Sie auf Falten, Dehnungsstreifen oder Kleberaustritt

- Geruchstest: Lösungsmittelhaltige Klebstoffe müssen vor dem Verpacken vollständig abgeblasen werden.

- Überprüfung beenden12: Unter schrägem Licht auf Riffelungen oder Leimglanz prüfen

✔ Eine Schachtel kann bei Tageslicht wunderschön sein, aber bei grellem Licht wird jede Naht und jedes Fältchen sichtbar.

Schlussfolgerung

Der richtige Klebstoff verwandelt PU-Leder von einem bloßen Überzug in ein luxuriöses, dauerhaftes Erlebnis.

Um es richtig zu machen:

- Passend zum Klebstoffformel auf Ihre Materialien und Anwendungsmethode

- Kontrollieren Sie Ihr Umwelt und Zeitdruck

- Verwenden Sie das richtige Werkzeuge für Ecken, Kurven und Überlagerungen

- Immer Testen Sie Ihre Verklebungstechnik vor der Ausweitung der Produktion

Denn bei einer luxuriösen Inneneinrichtung beginnt ein makelloses Finish immer mit dem, was darunter liegt.

Markenname: WoodoBox

Slogan: Maßgefertigte Holzkisten, handwerklich perfekt gefertigt

Website: www.woodobox.com

-

Die Kenntnis von Haftklebstoffen kann Ihnen helfen, den richtigen Klebstoff für die effektive Verklebung von PU-Leder auszuwählen. ↩

-

Erfahren Sie mehr über die Blasenbildung auf der Oberfläche, um häufige Fallstricke bei Ihren Klebeprojekten zu vermeiden und ein makelloses Ergebnis zu erzielen. ↩

-

Erfahren Sie, welche Risiken die Verwendung der falschen Klebstoffformel birgt, um Delaminationen zu vermeiden und die Haltbarkeit Ihrer Projekte zu gewährleisten. ↩

-

Unter diesem Link finden Sie die effektivsten Klebstoffe, die speziell für enge Kurven und komplizierte Oberflächen entwickelt wurden und eine starke Verbindung gewährleisten. ↩

-

Erfahren Sie mehr über die Vorteile von wasserbasierten PU-Klebstoffen, einschließlich ihrer Umweltfreundlichkeit und ihrer Eignung für empfindliche Materialien. ↩

-

Erfahren Sie, wie PU-Schmelzklebstoff in automatisierten Prozessen eingesetzt wird, um saubere und feste Verbindungen in der Fertigung zu gewährleisten. ↩

-

Wenn Sie wissen, wie sich Luftfeuchtigkeit und Temperatur auf die Trocknung auswirken, können Sie Ihren Verpackungsprozess optimieren und bessere Ergebnisse erzielen. ↩

-

Die Erforschung der Auswirkungen der Klebstoffdicke kann zu einer besseren Haftung und Effizienz bei Ihren Projekten führen. ↩

-

Wenn Sie sich über verschiedene Trägermaterialien informieren, können Sie die besten Optionen für Ihre Verpackungsanforderungen auswählen. ↩

-

Wenn Sie den Schältest verstehen, können Sie Ihr Wissen über Qualitätssicherungsmethoden erweitern und eine bessere Produkthaltbarkeit gewährleisten. ↩

-

Die Untersuchung der Hitzeeinwirkung hilft Ihnen zu verstehen, wie sich die Temperatur auf die Haltbarkeit von Verpackungen auswirkt, was für Lieferungen im Sommer entscheidend ist. ↩

-

Eine Überprüfung des Finishs ist für ein luxuriöses Erscheinungsbild unerlässlich; erfahren Sie mehr, um sicherzustellen, dass Ihre Produkte herausragen. ↩